Survey of Audio Footer Designs

Stray vibrations from loudspeakers can directly transmit into the surfaces of the room through contact with the floor. This causes the surfaces of the room to sympathetically radiate these vibrations as audible noise which can affect the music listening experience. The problem is further compounded by the large surface area of the room which radiates sound with a high efficiency. Low frequency vibrations are the worst offender due to their ability to travel throughout the structure of the room with little impedance.

Even with basic vibration isolation, these degrading effects of structure-borne vibrations can be mitigated. Placing vibration isolating audio footers under loudspeakers reduces reverberation time, vibration decay artifacts, and distortion at some frequencies[1]. Similar positive effects are experienced by isolating audio electronics from vibrations. The degree of these benefits can vary widely between audio footer designs.

Measuring Vibration Isolation

We sought to measure the vibration isolation performance of several popular audio footer designs. We then measured our Carbide Base footers under the same criteria for comparison. Vibration isolation was measured for each audio footer in horizontal and vertical directions. Three different vibration sources were utilized to generate vibrations: an electromagnetic vibration table, a subwoofer, and a 2-way loudspeaker. In each experiment, four audio footers were placed on top of the vibration source and then an aluminum plate was placed on top of the audio footers. Weights were bolted to the aluminum plate to simulate the mass of a loudspeaker or audio equipment having a total mass approximately 32 kg (70 lbs). Measurement Specialties ACH-01 piezoelectric accelerometer sensors were then attached to the plate with double sided tape to measure acceleration in the horizontal and vertical directions.

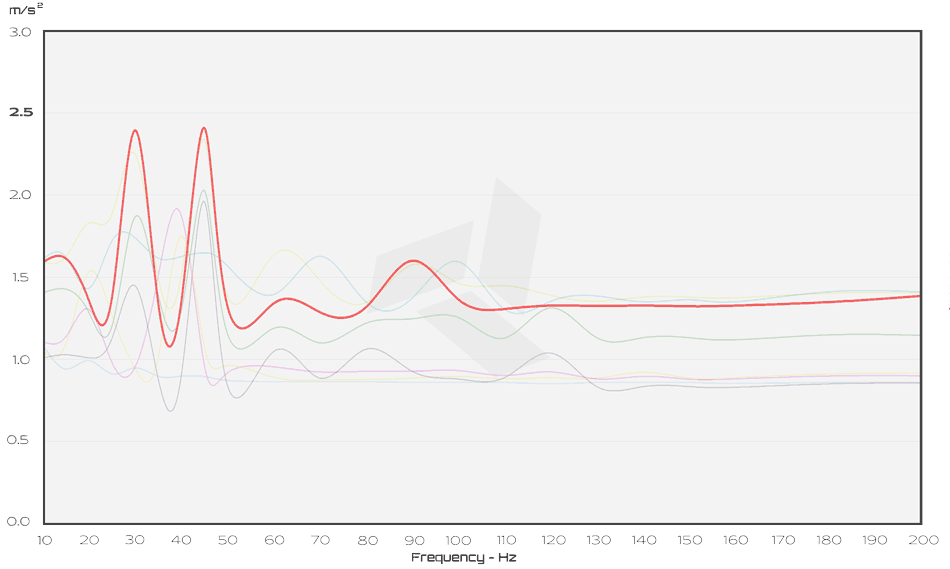

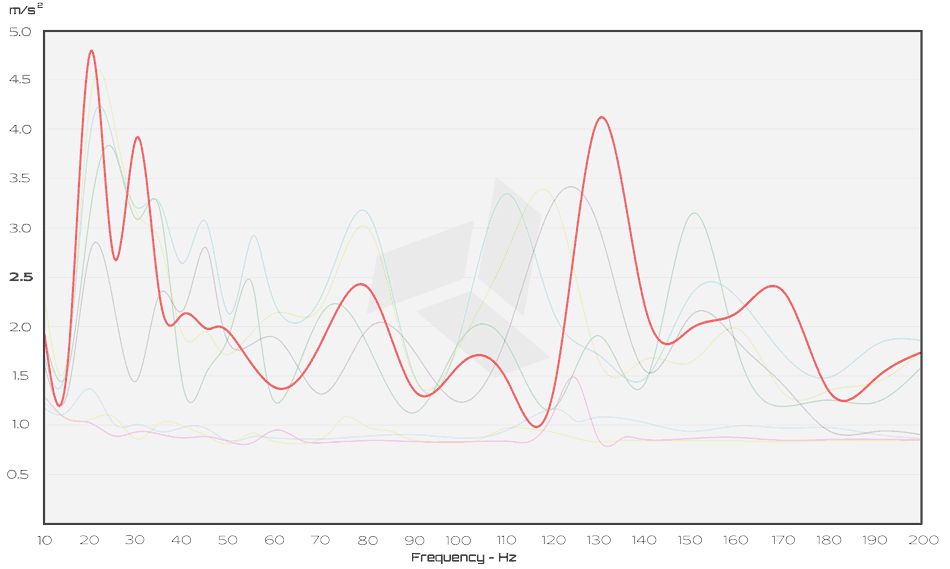

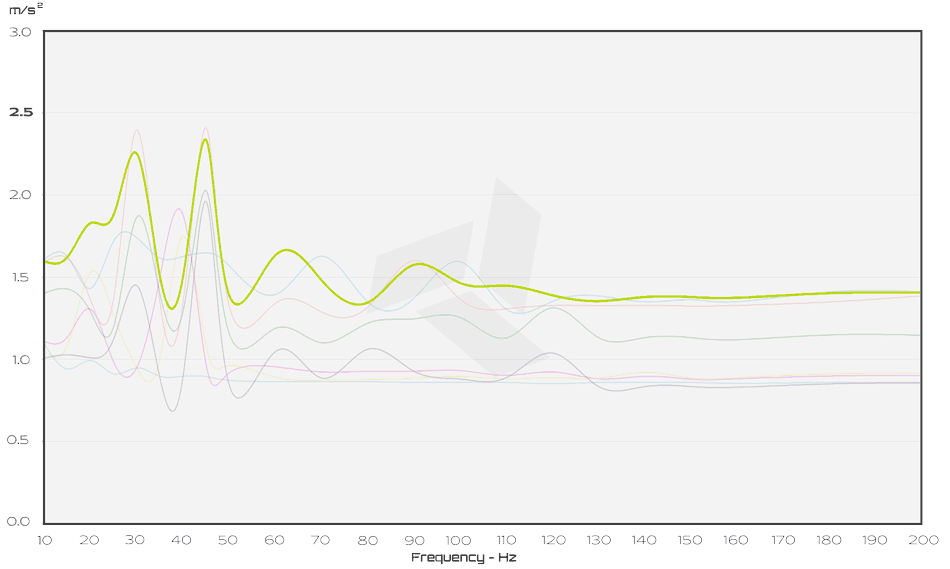

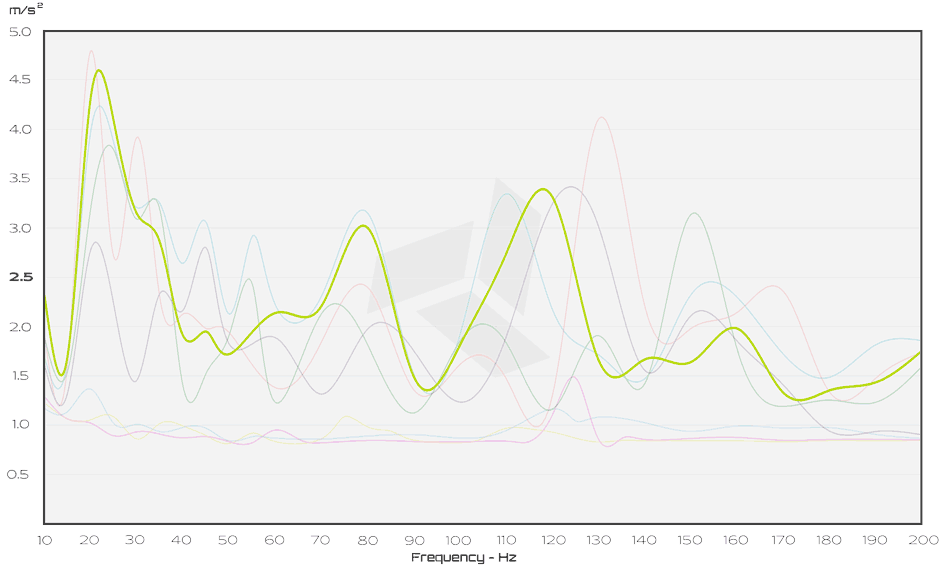

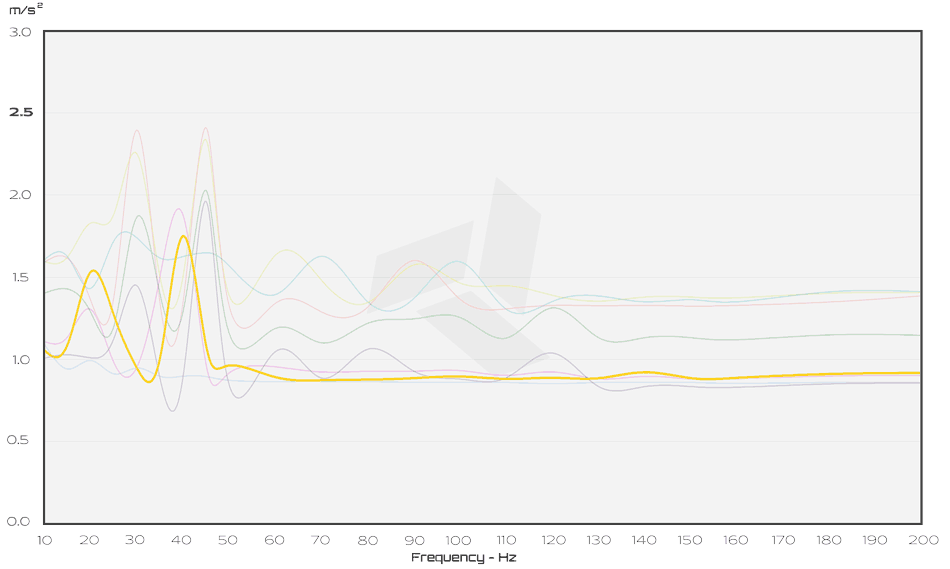

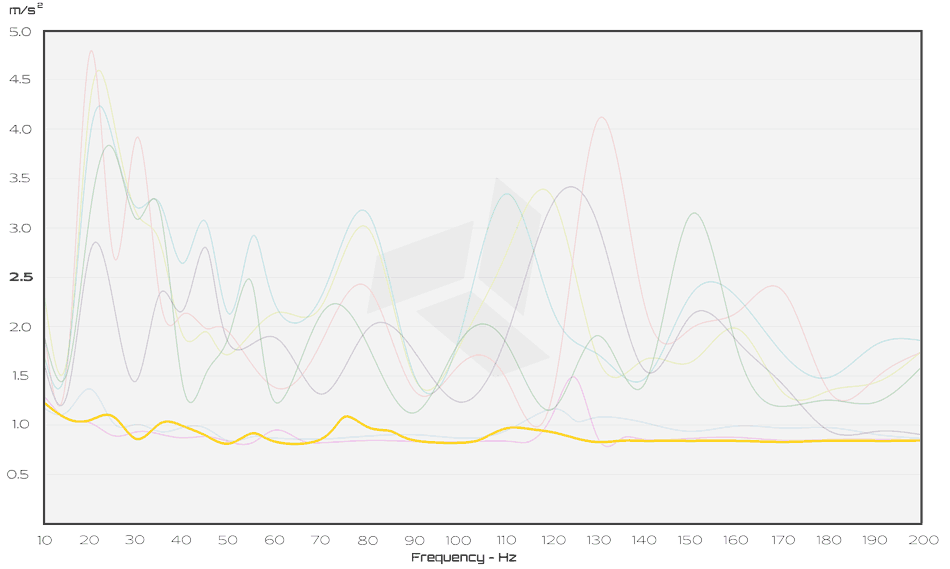

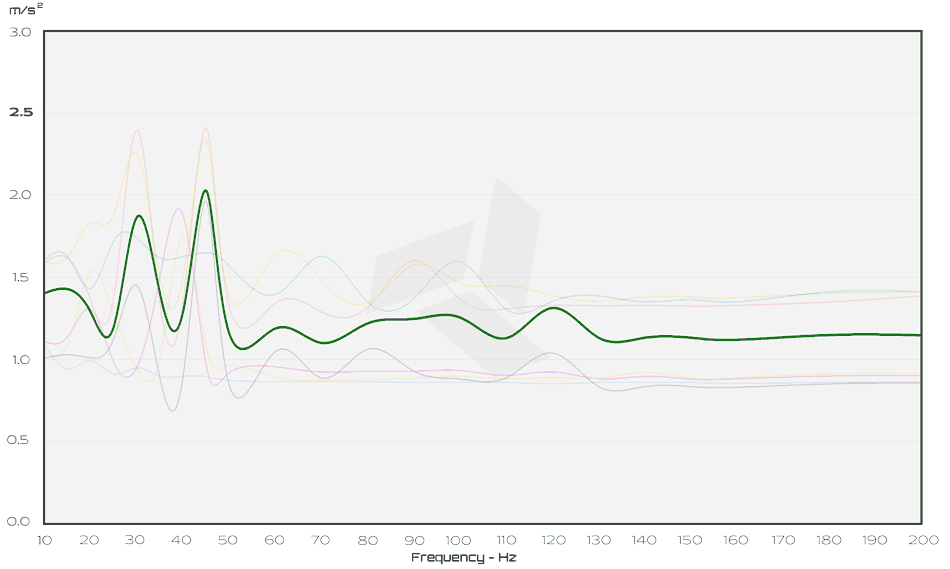

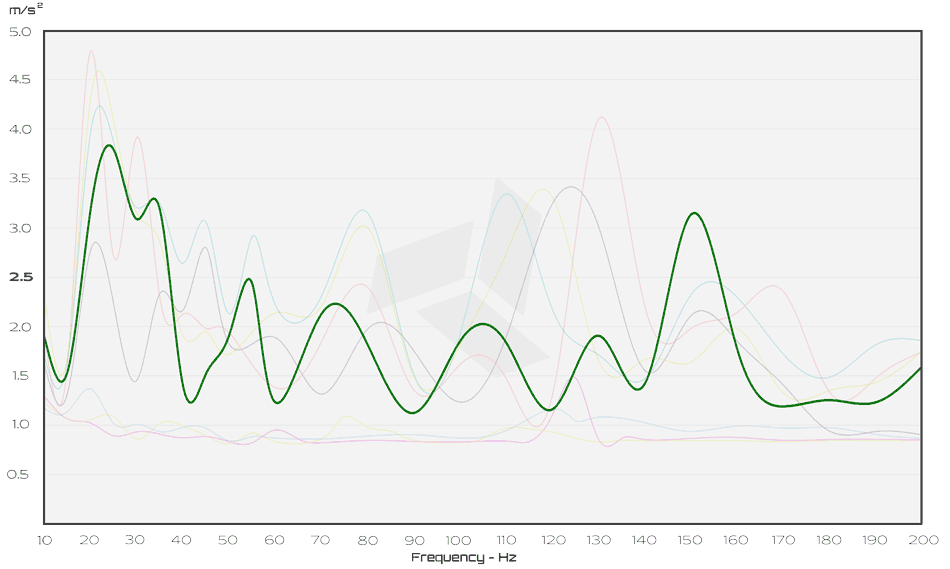

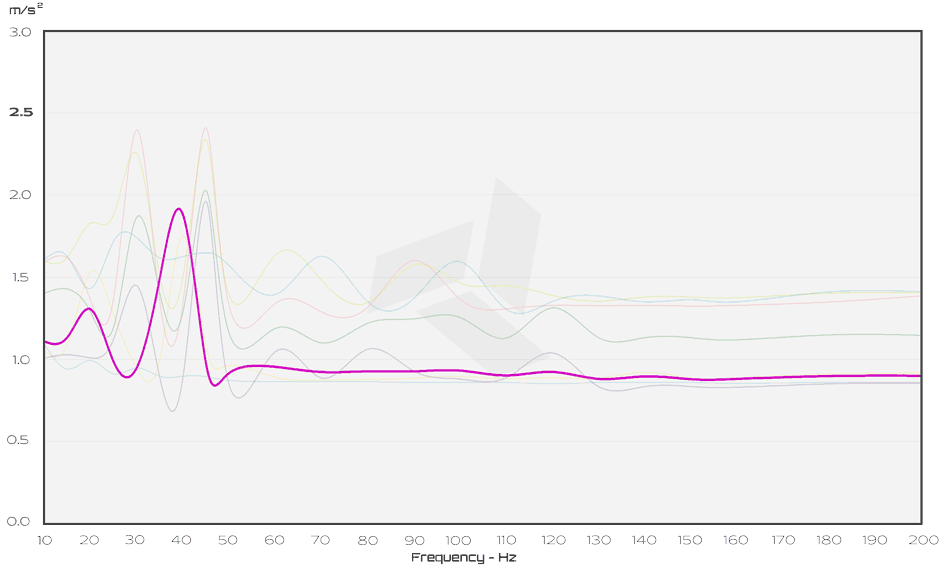

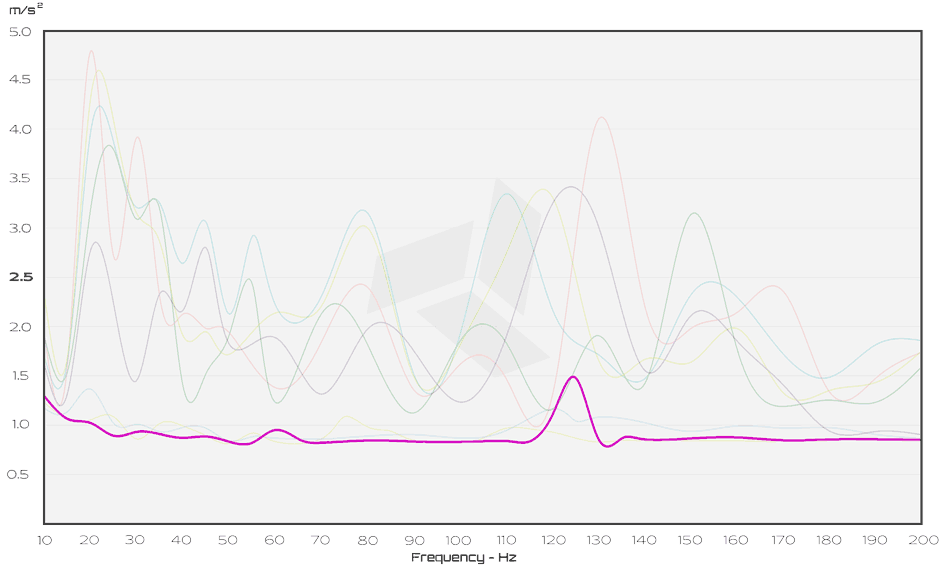

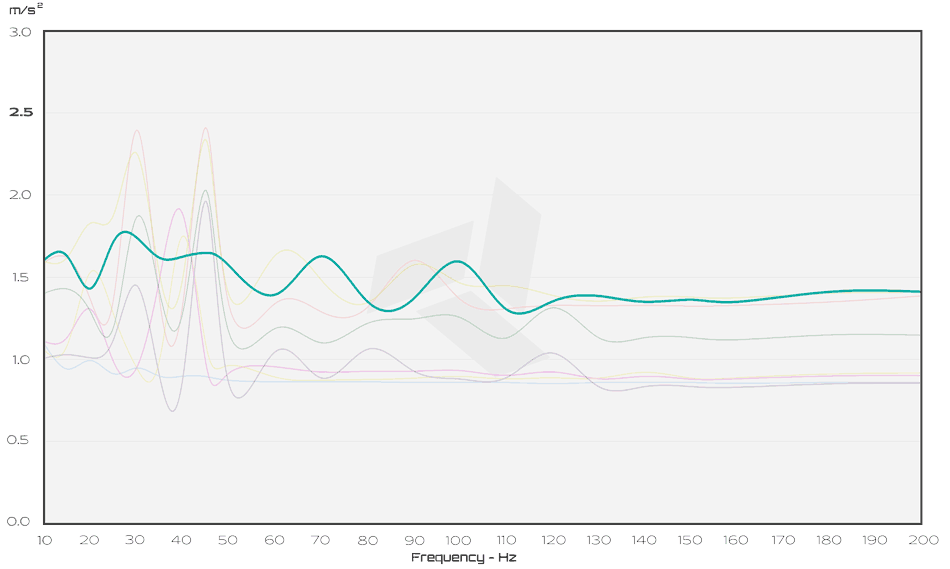

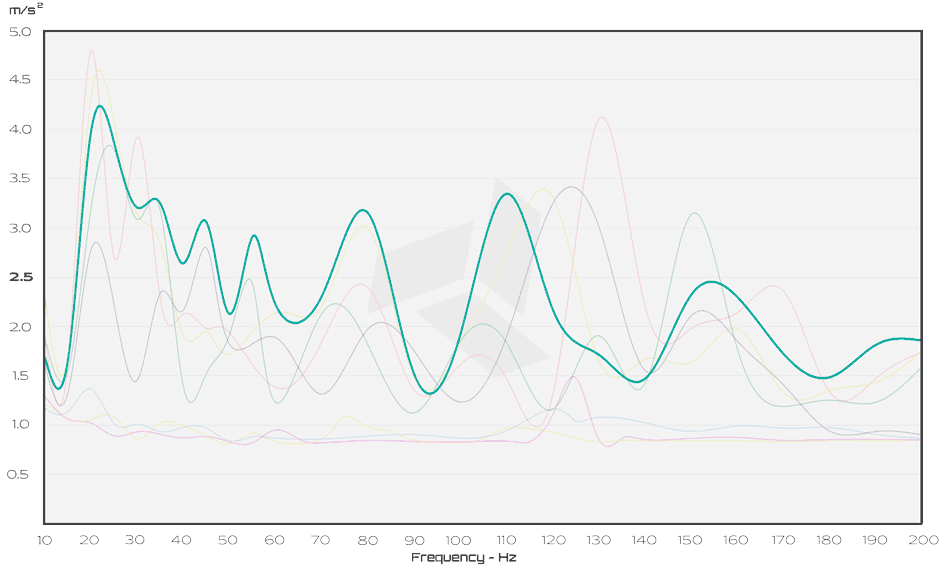

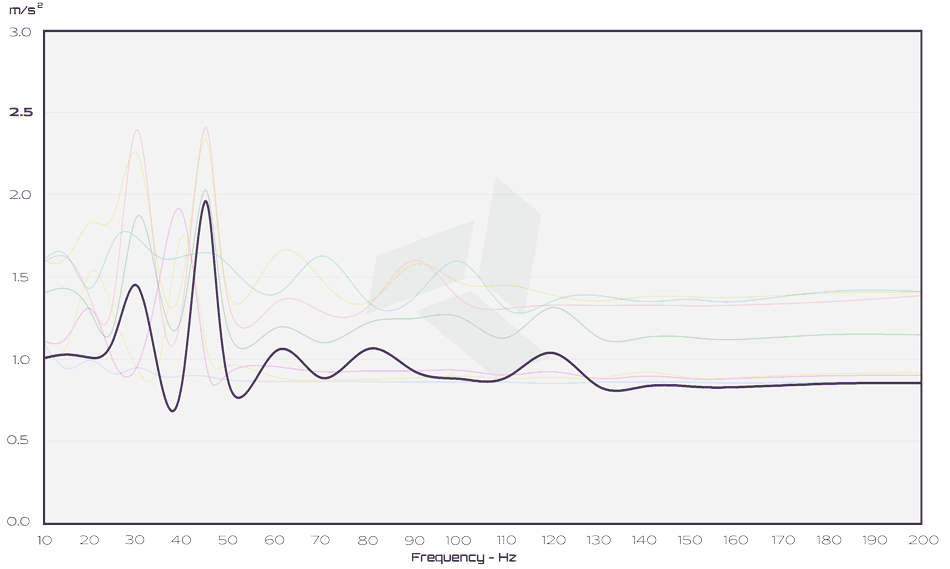

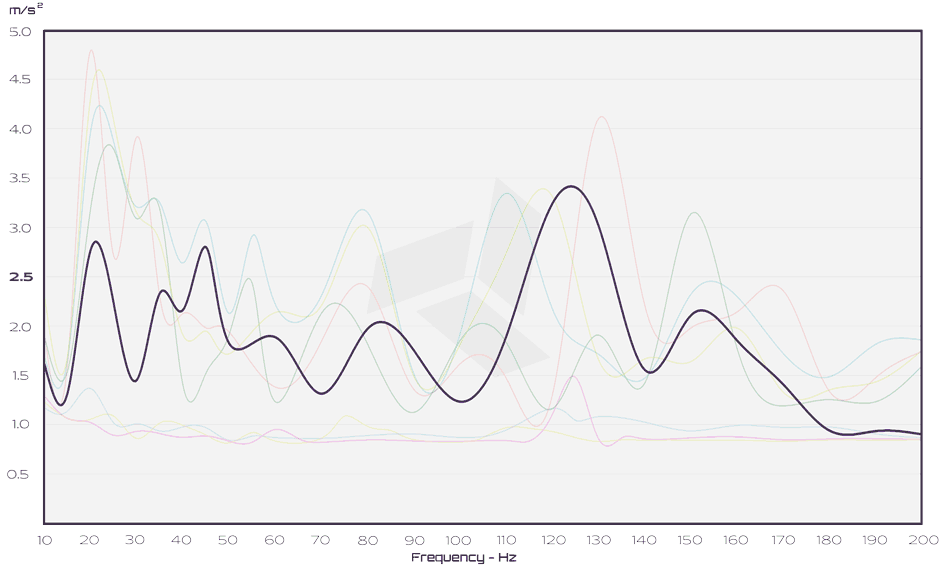

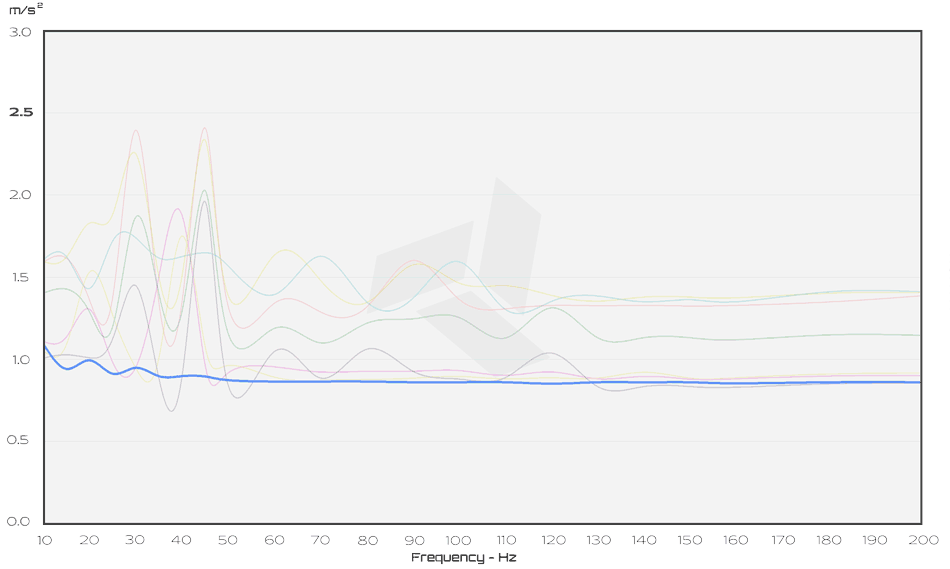

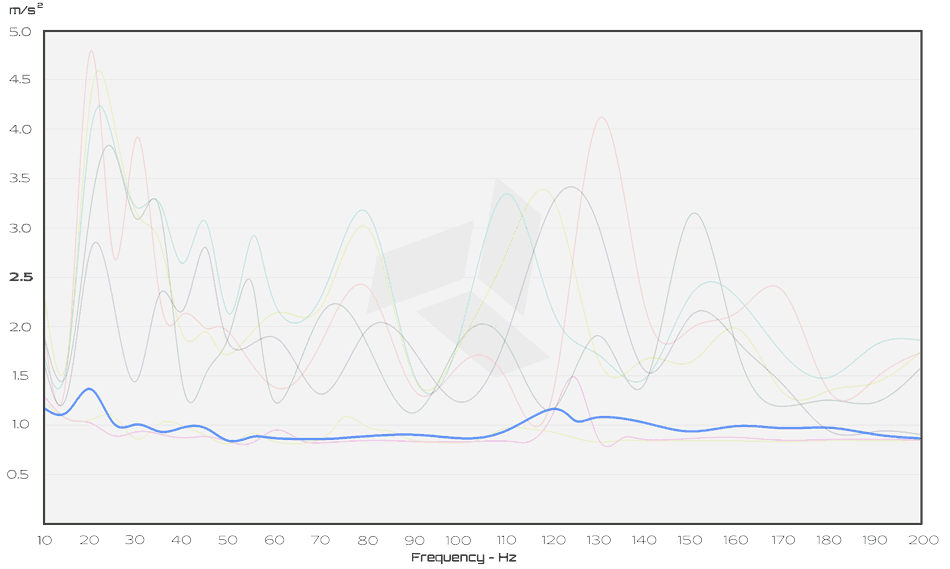

Electromagnetic Vibration Table

An electromagnetic vibration table was used to obtain the first set of measurements. The table was digitally controlled to modulate the vibration amplitude and frequency of the table surface. To determine the vibration amplitude of the table, an accelerometer sensor was attached to the table and then a multimeter was used to measure the output of the sensor amplifier. The same was done with a second accelerometer sensor attached to the aluminum plate. Measurements were taken from the plate sensor in 5 Hz intervals from 10 Hz to 200 Hz. The vibration table was adjusted at each interval to ensure the table vibrated with an acceleration of 2.5 m/s2. These measurements were focused on the bass frequency region in order to determine the vibration isolation performance around the resonance frequency of each audio footer.

The advantage of this experiment was that the table offered consistent vibrations across the measurements. This allowed resonances in the audio footers to be clearly identifiable. The disadvantage of this experiment was its limited resolution due to the spaced measurements. This experiment also did not offer any insight into the vibration decay behavior.

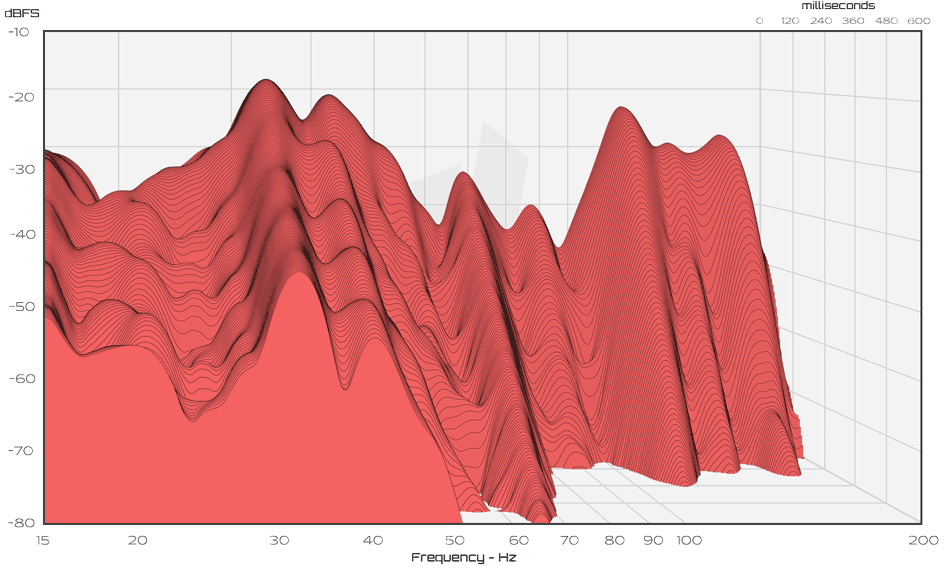

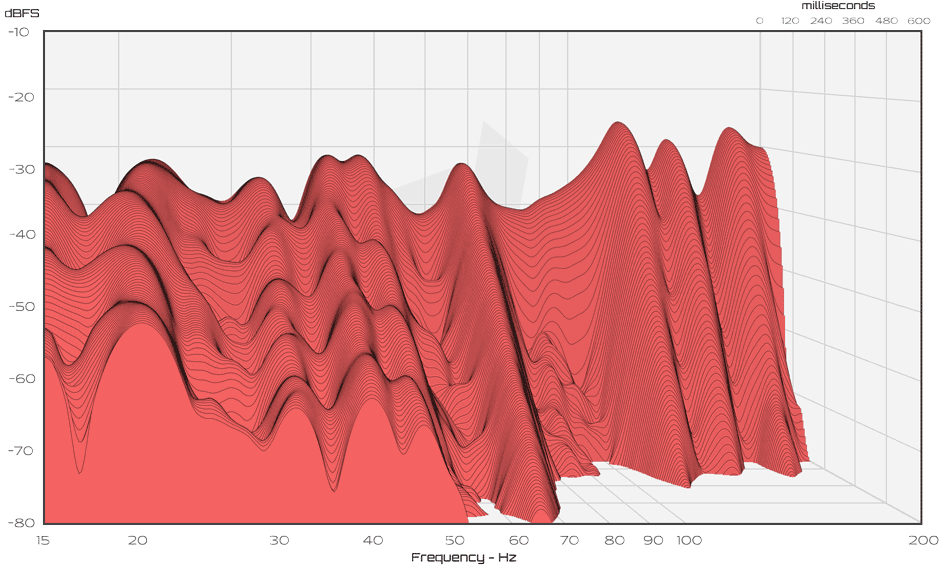

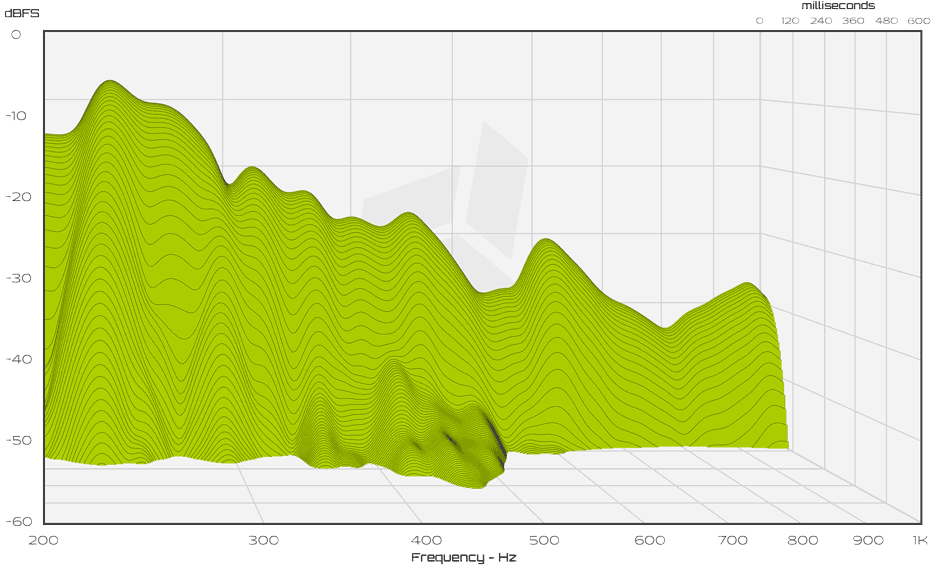

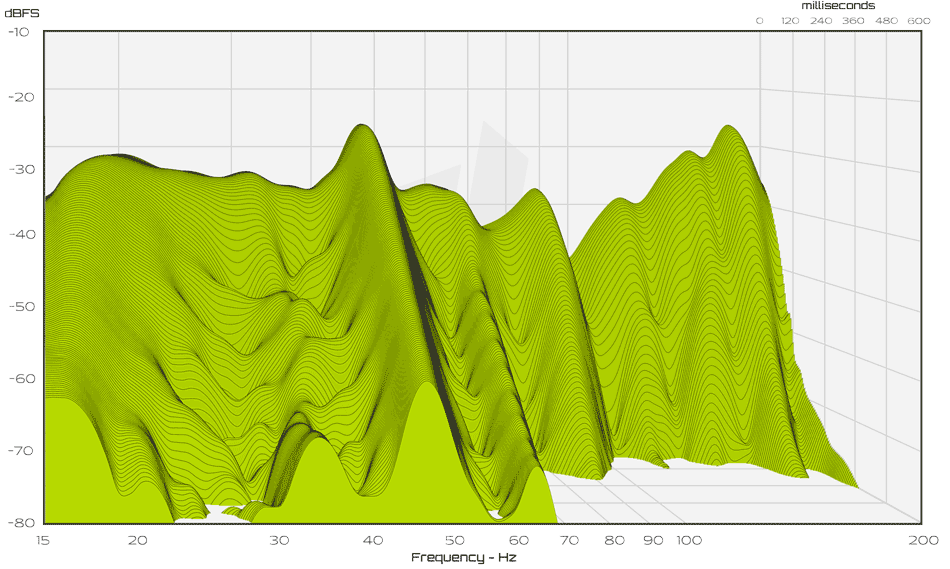

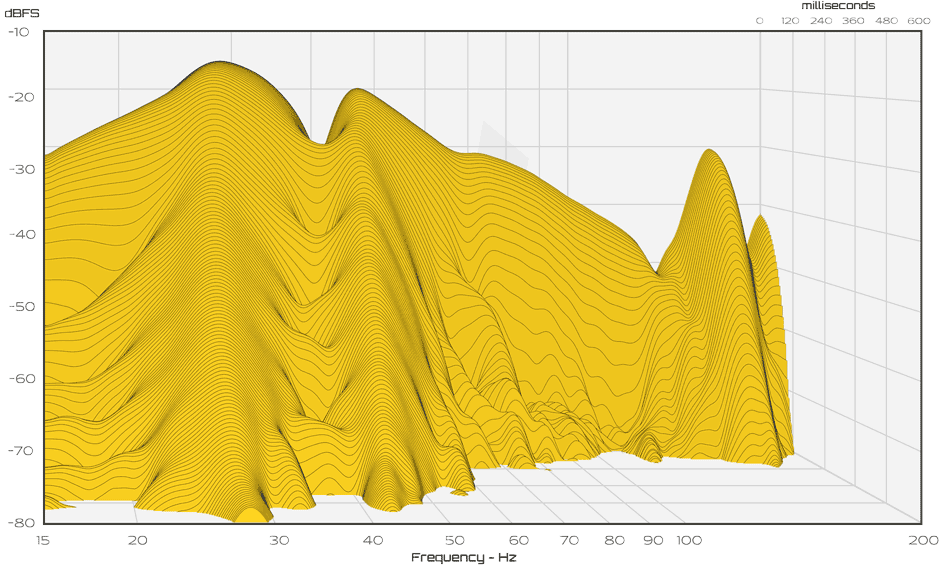

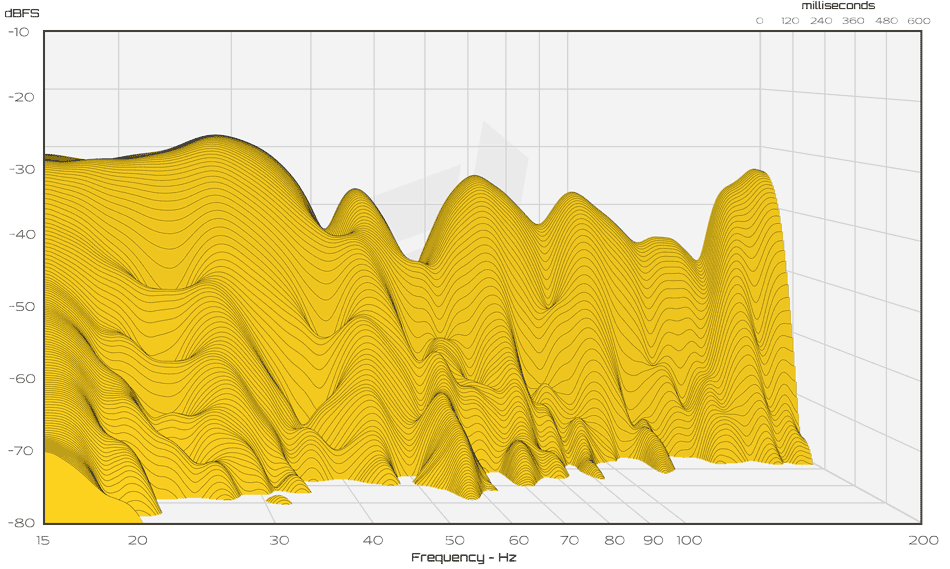

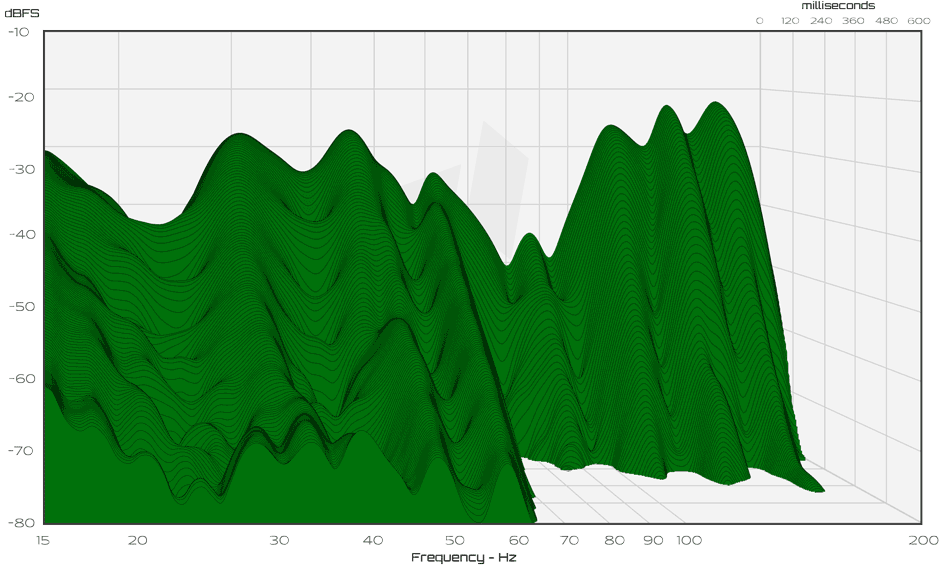

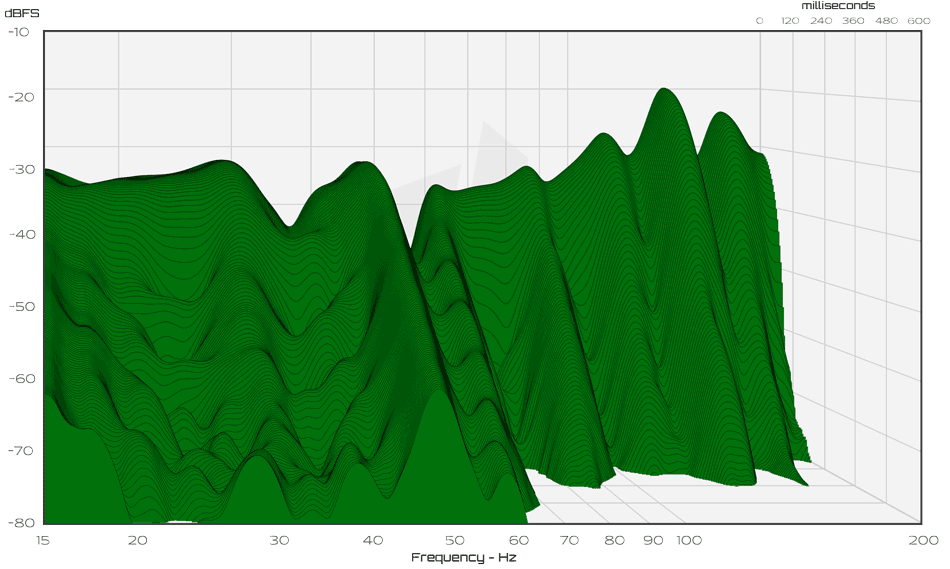

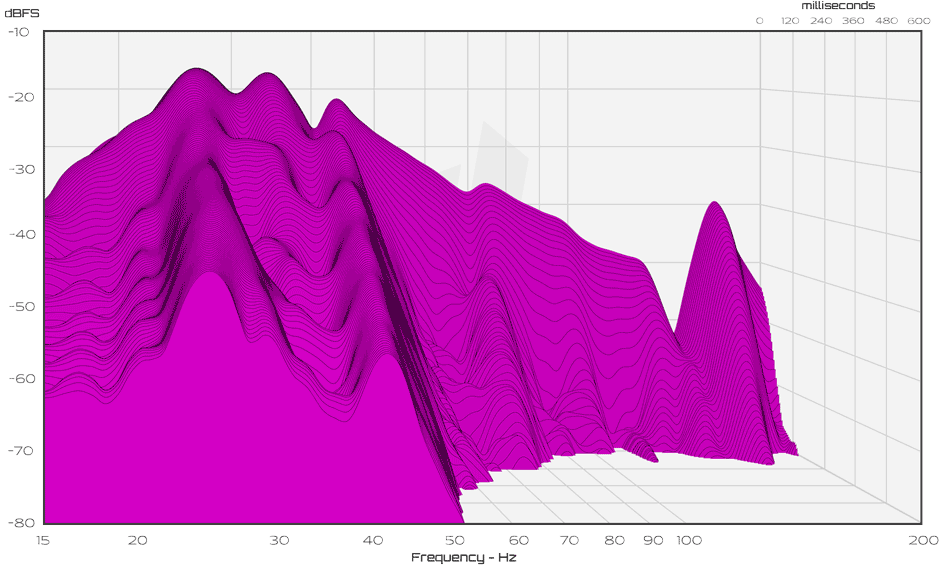

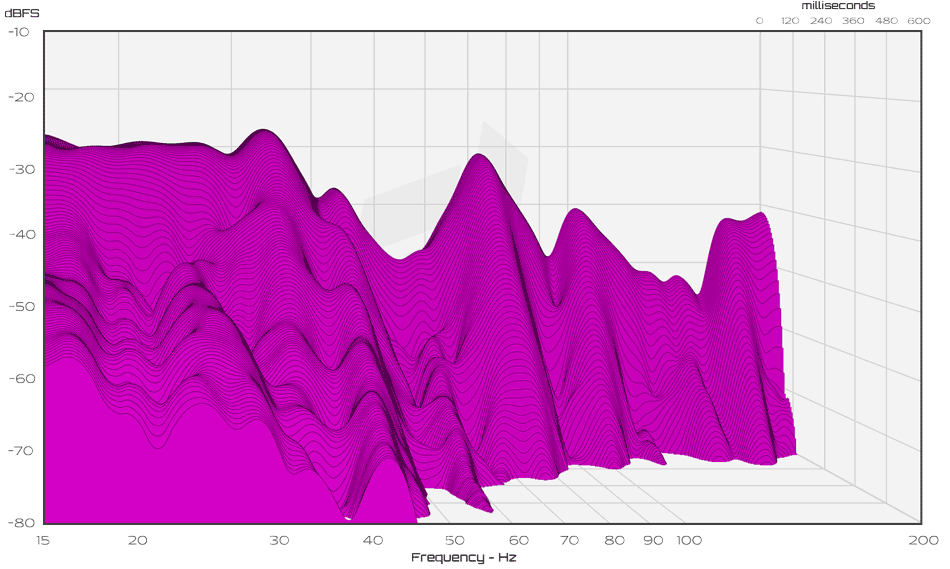

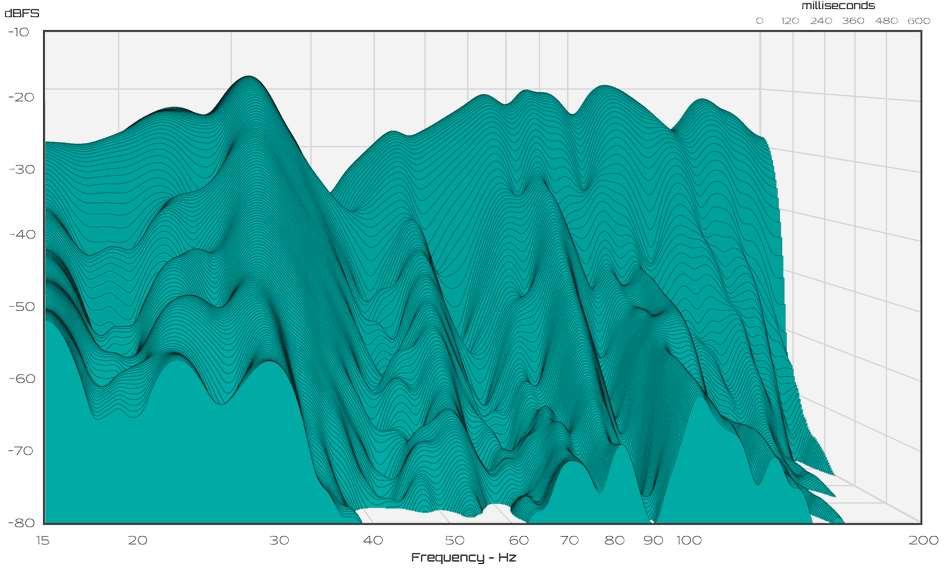

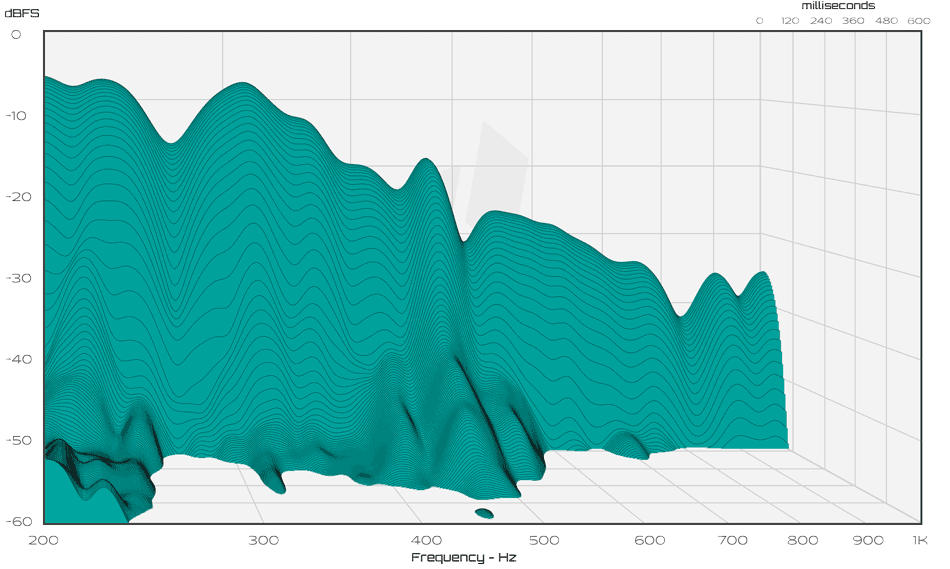

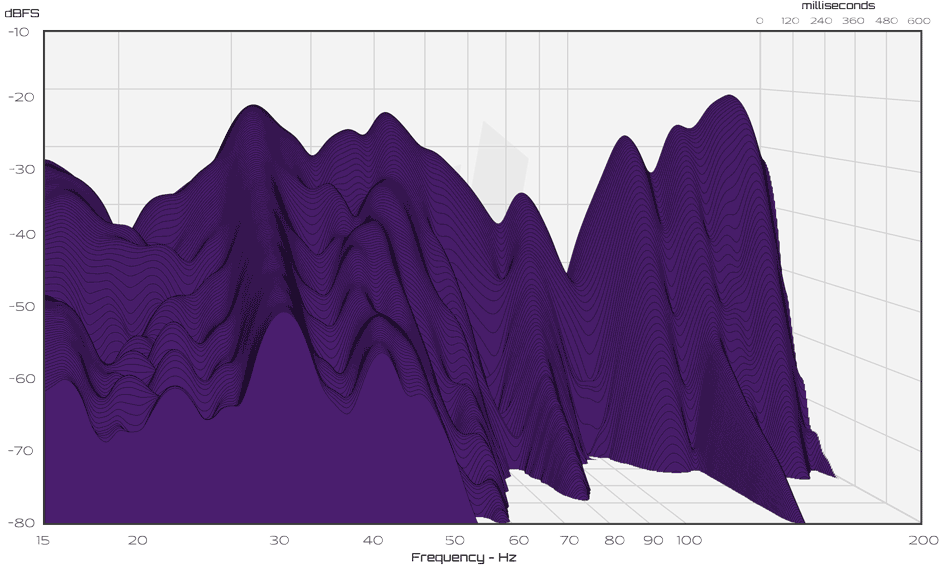

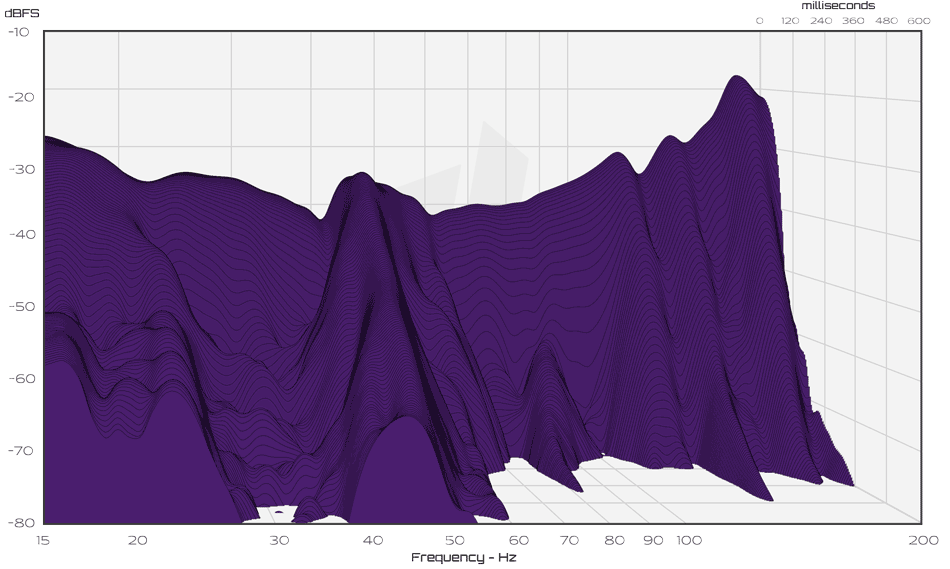

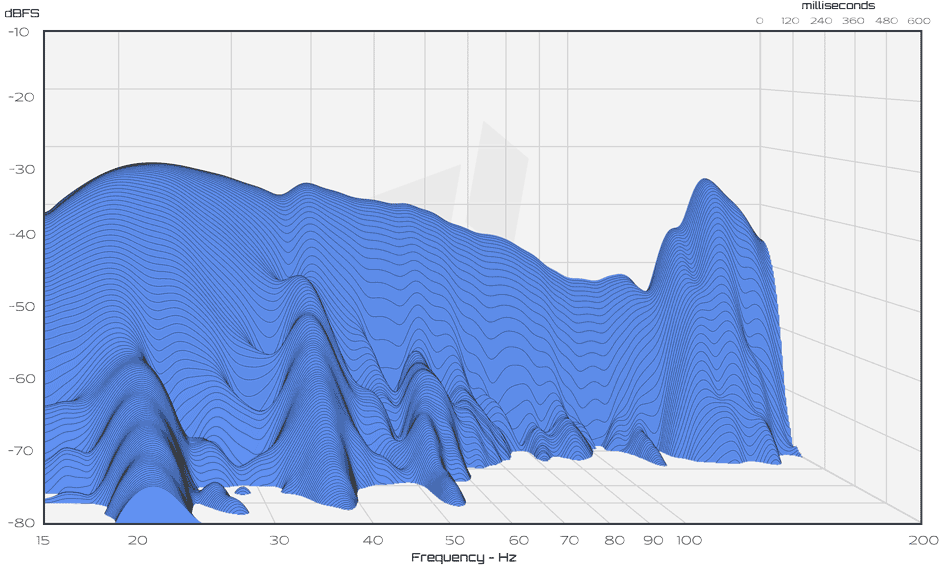

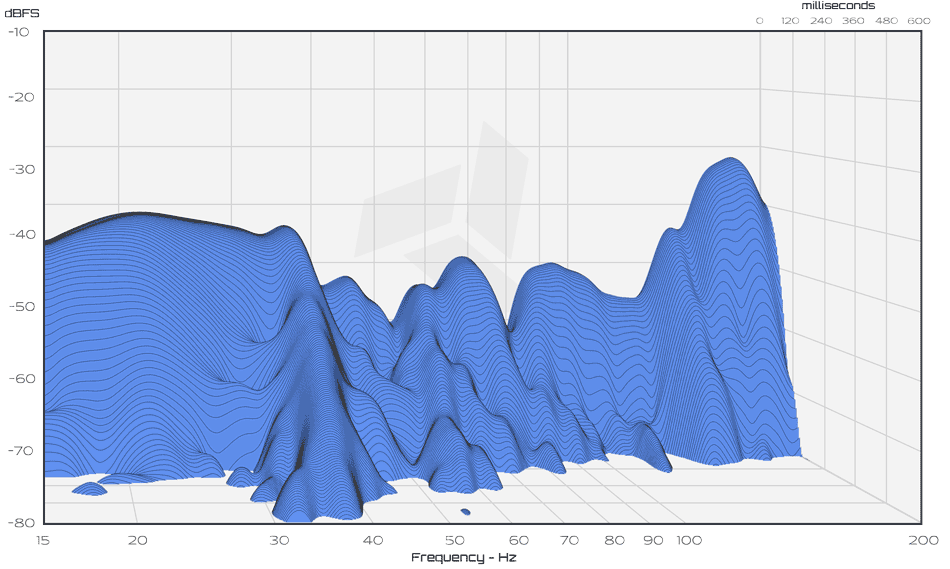

Subwoofer

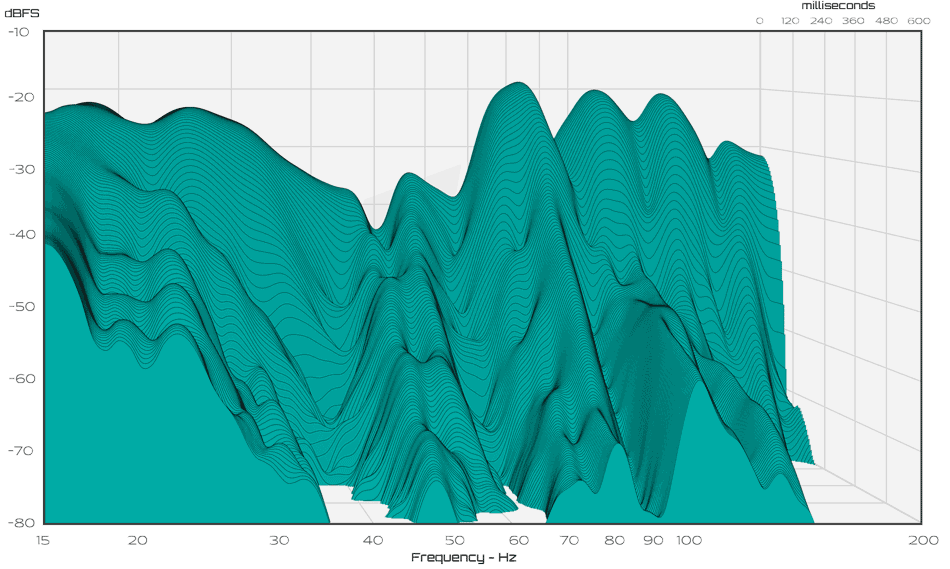

A subwoofer was used as a vibration source to obtain sweep measurements in the bass frequency region. A PC was used used to generate a log swept sine signal from 15 Hz to 200 Hz which was then played through the subwoofer. The accelerometer sensors were attached to the forward edge and top of the plate to simultaneously measure horizontal and vertical vibrations. The PC was used to record the output of the plate mounted sensors. The measurements were then translated into waterfall graphs showing the vibration decay. The Y-Axis of the waterfall graphs were set to to ignore noise floor artifacts, where 0 dBFS corresponded to the limit before clipping. The maximum SPL during the sweep was 93 dBA as measured on the floor of our reverberant factory at a distance of 1 m . The maximum horizontal cabinet acceleration experienced during the sweep was 2.4 m/s2.

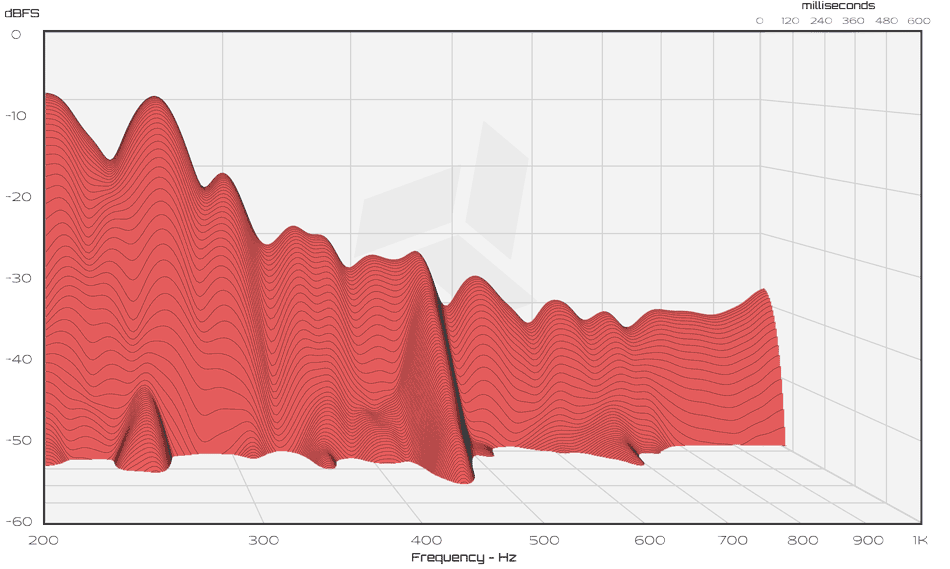

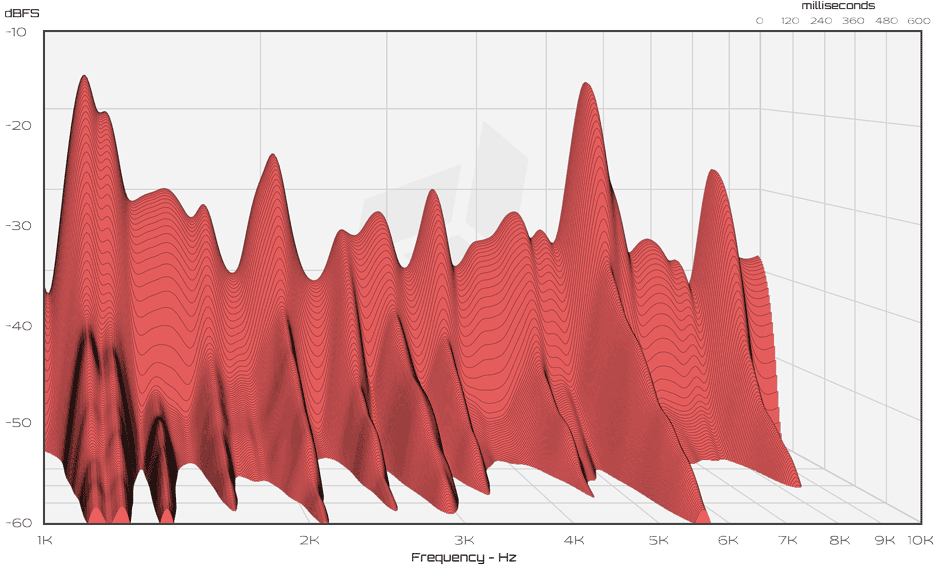

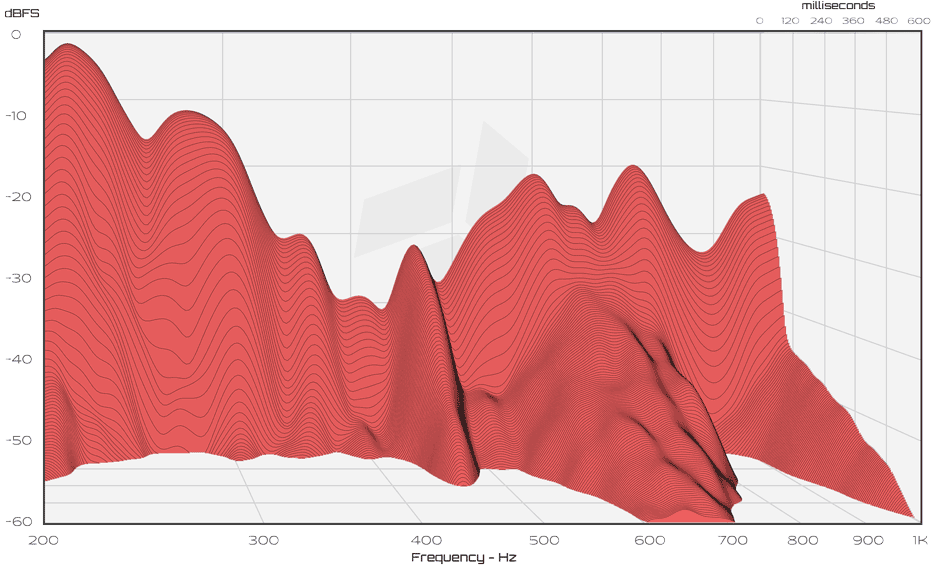

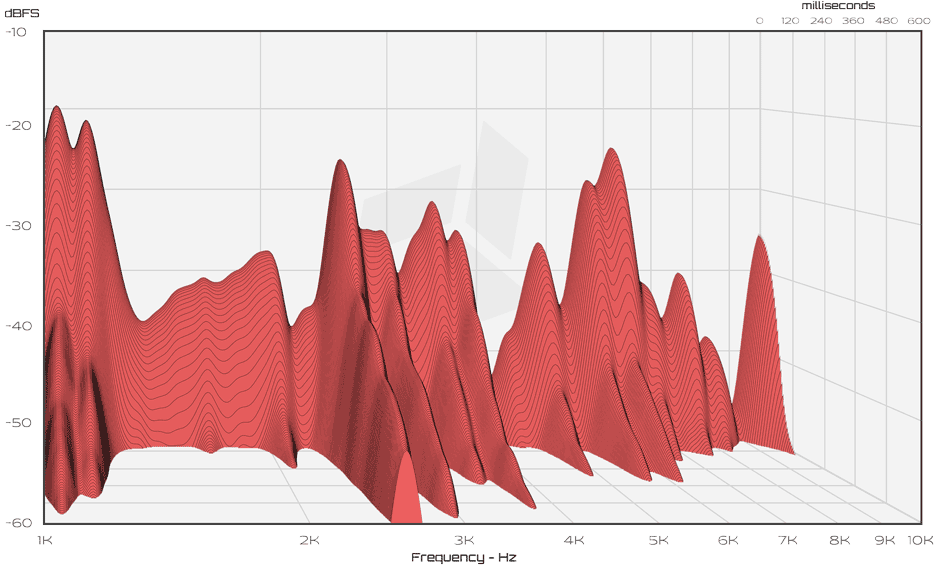

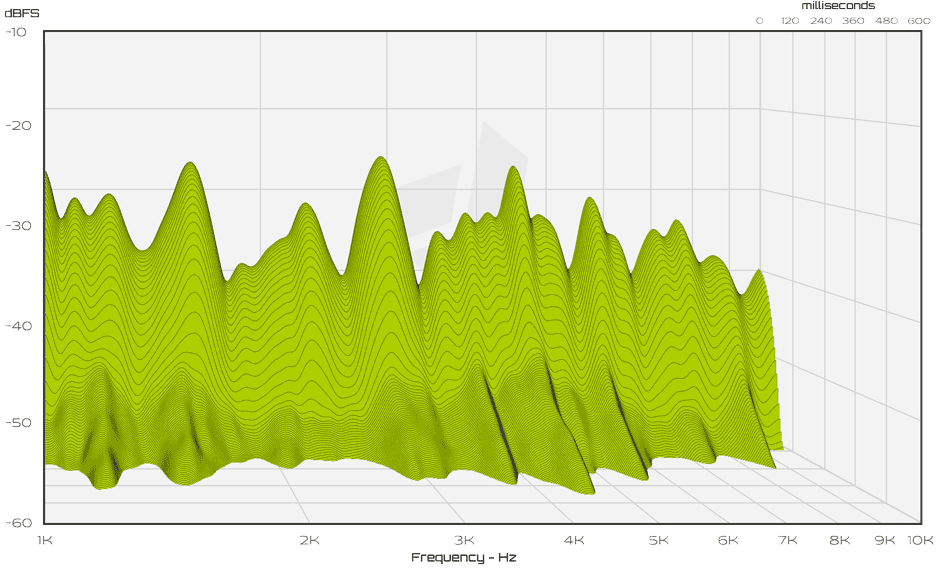

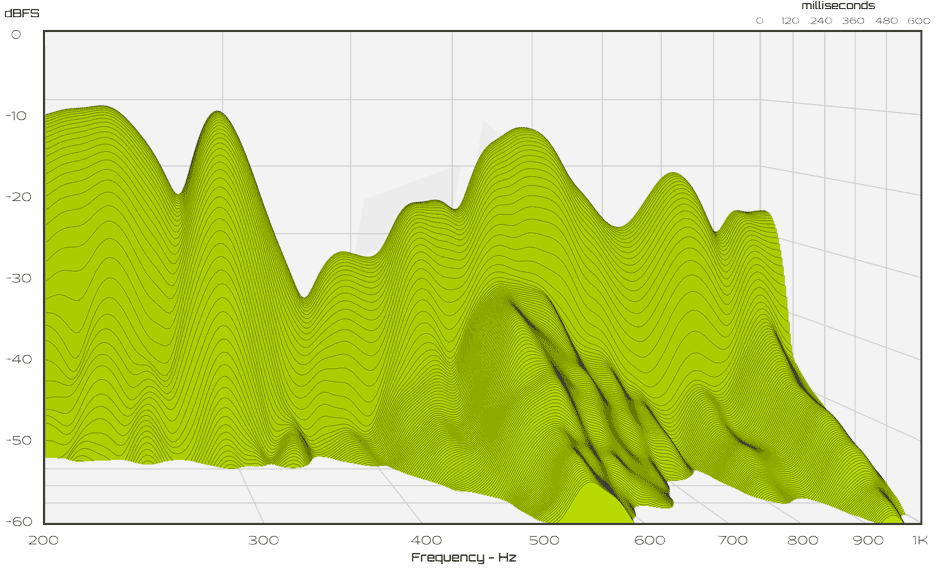

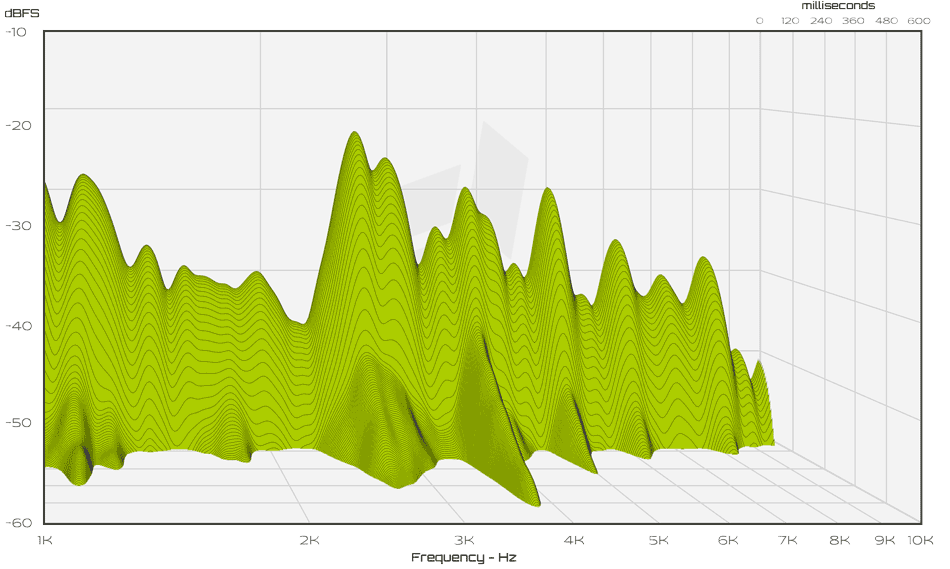

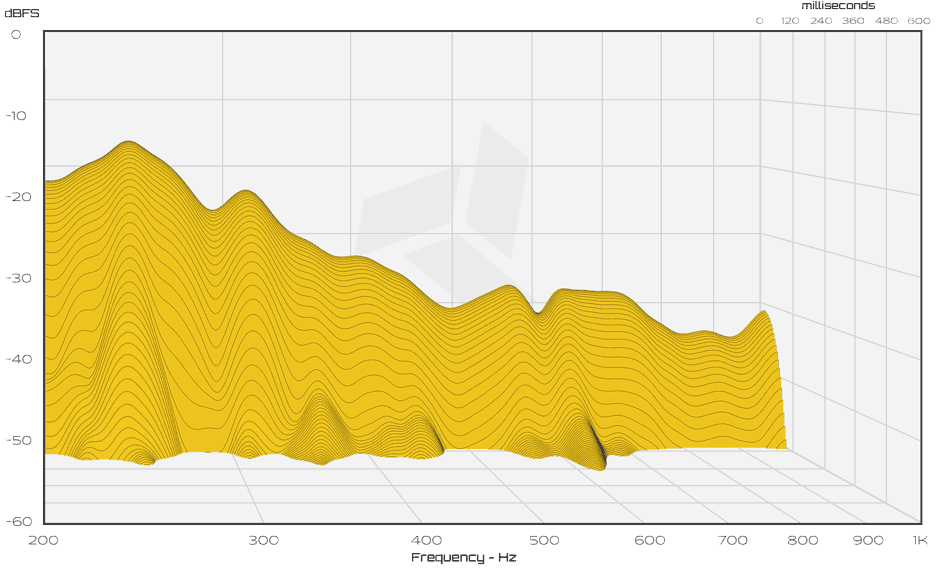

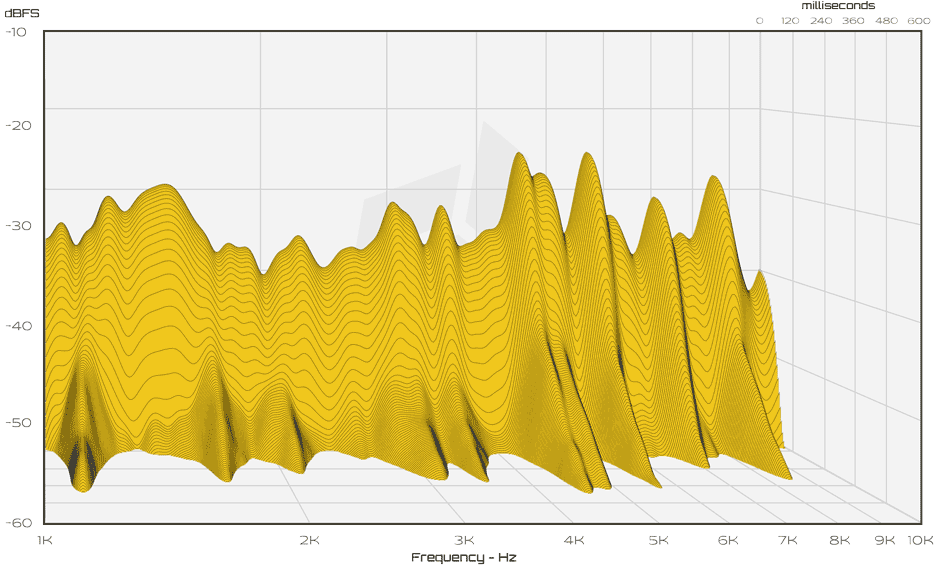

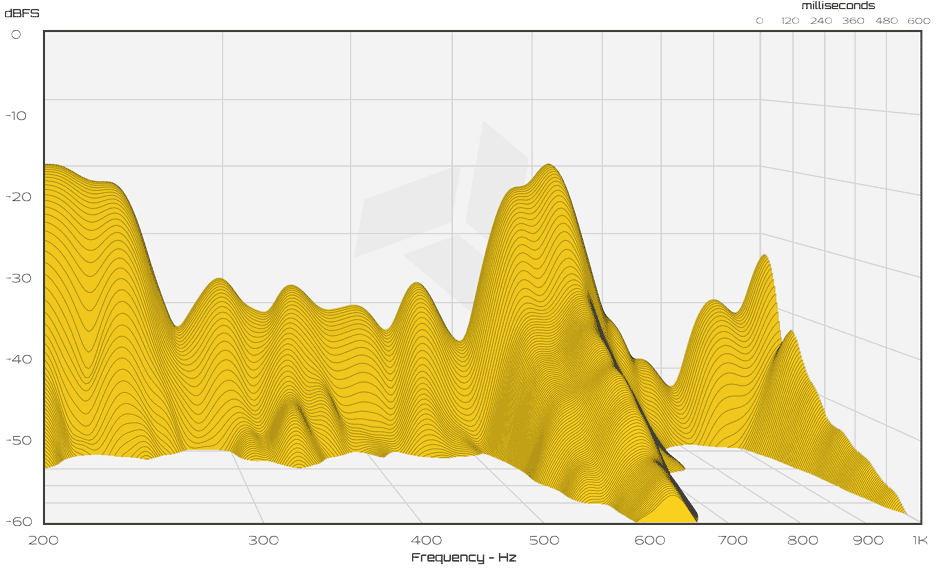

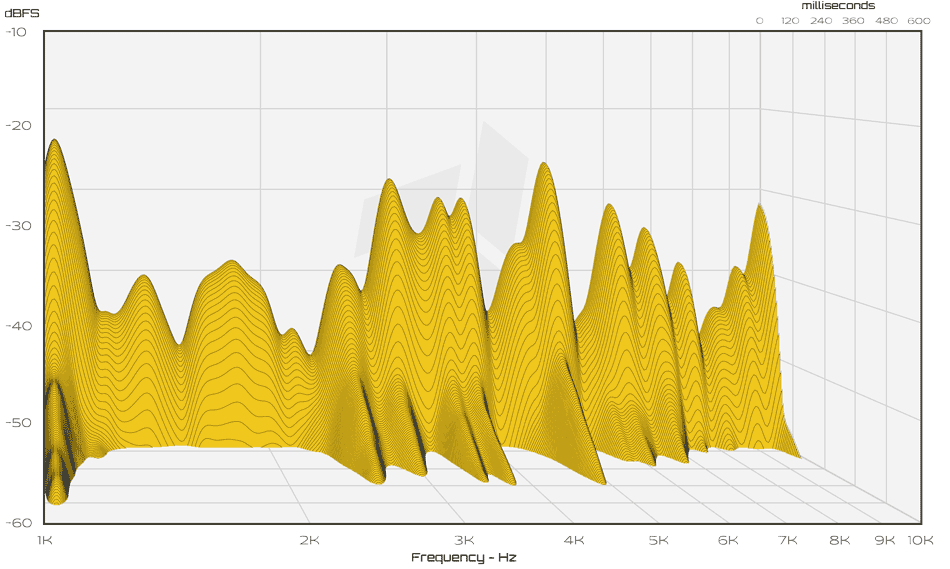

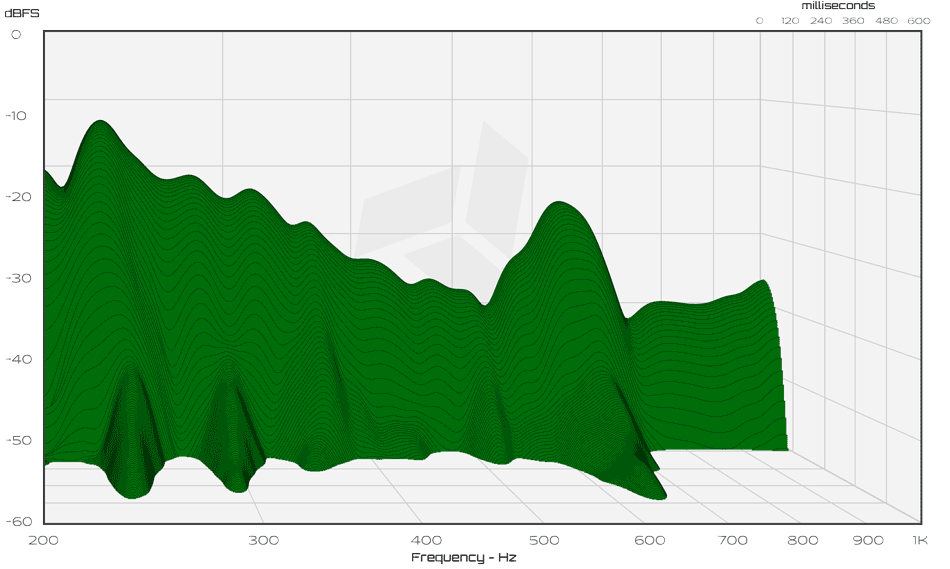

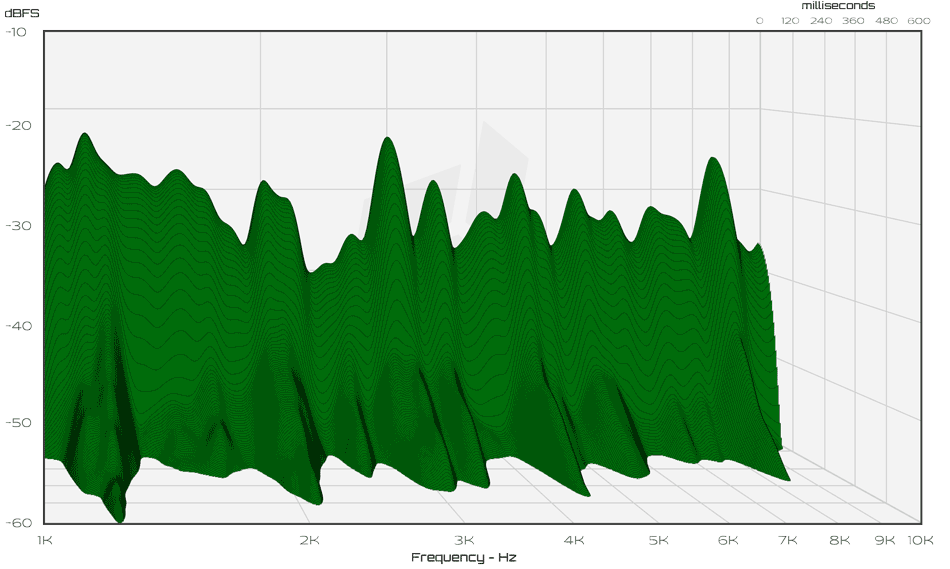

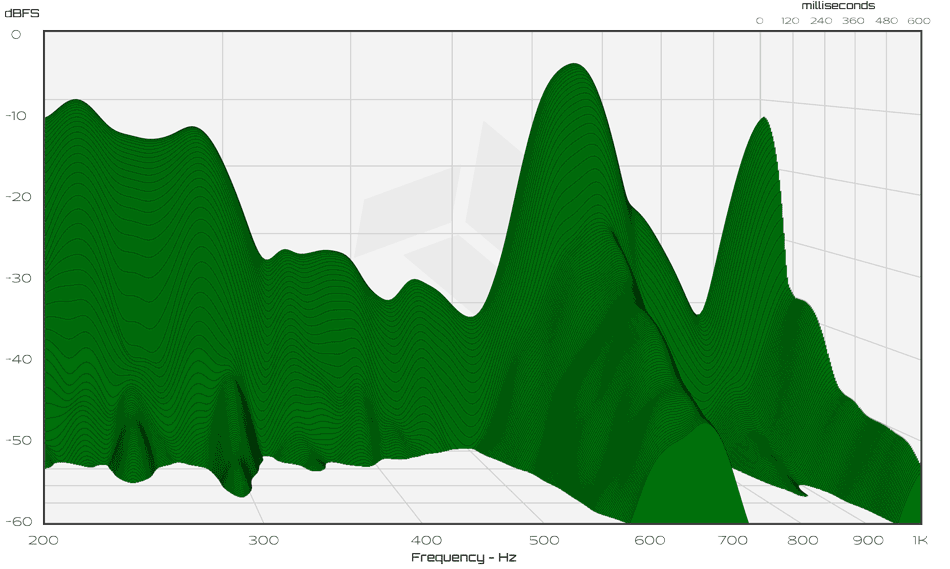

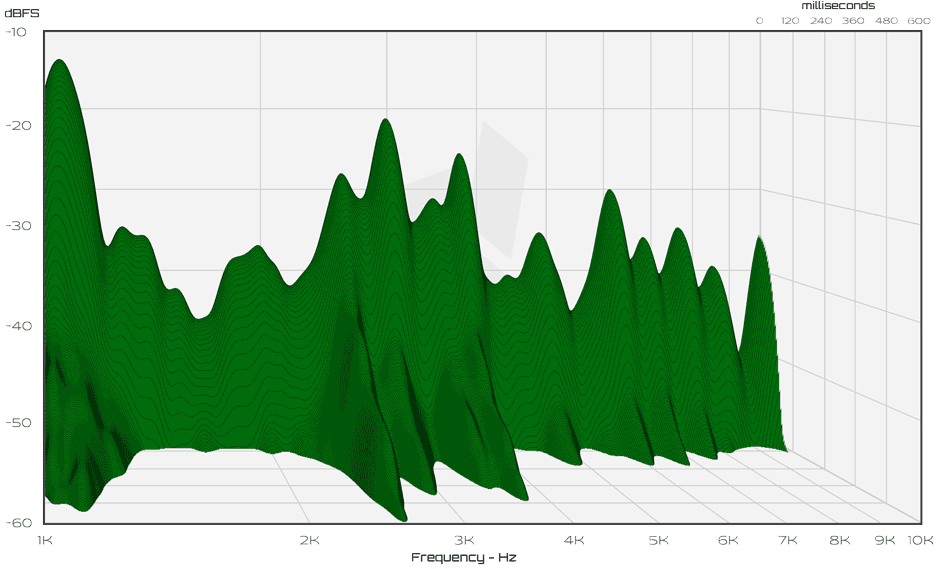

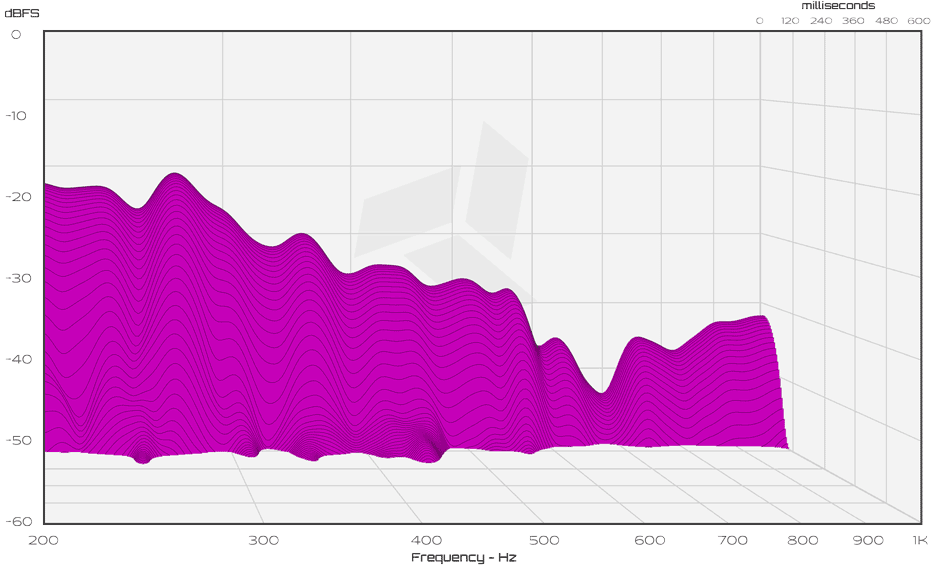

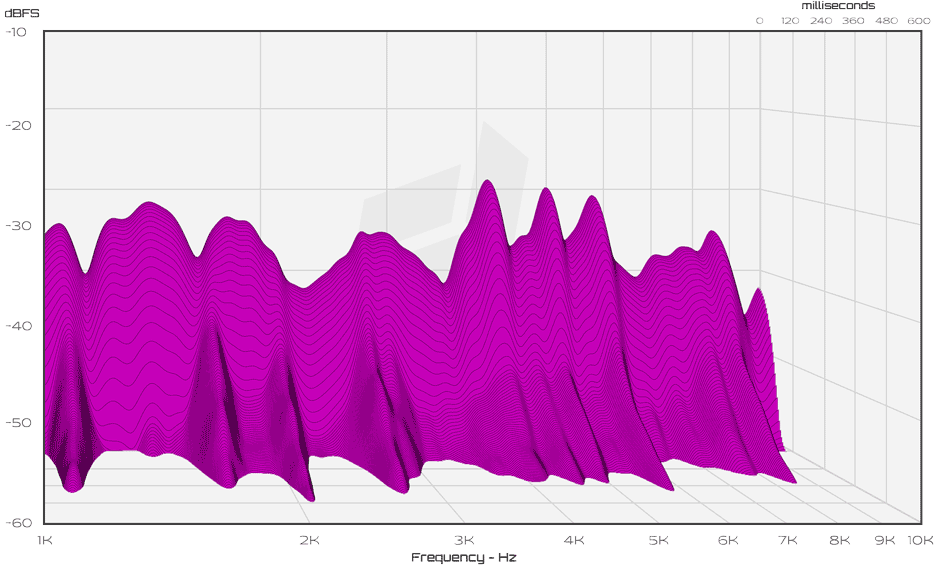

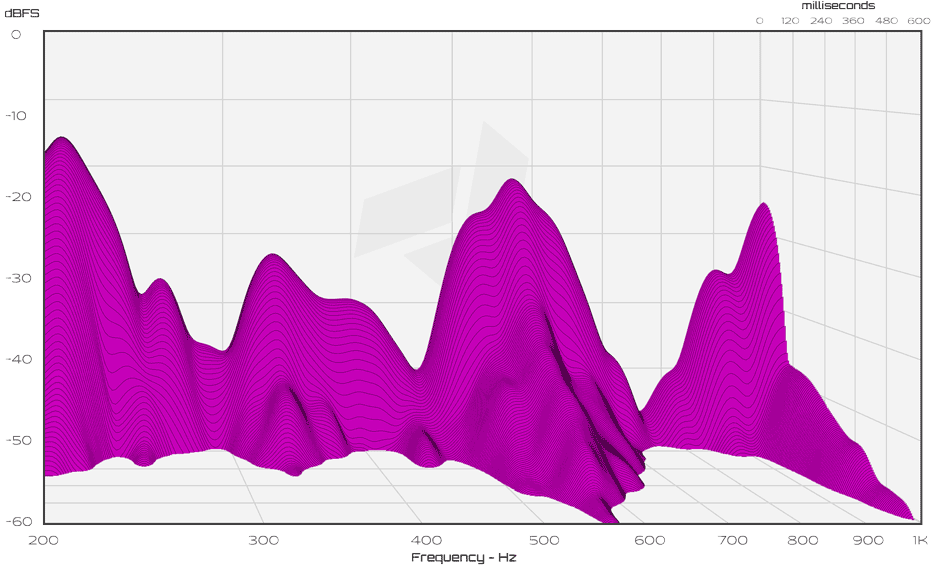

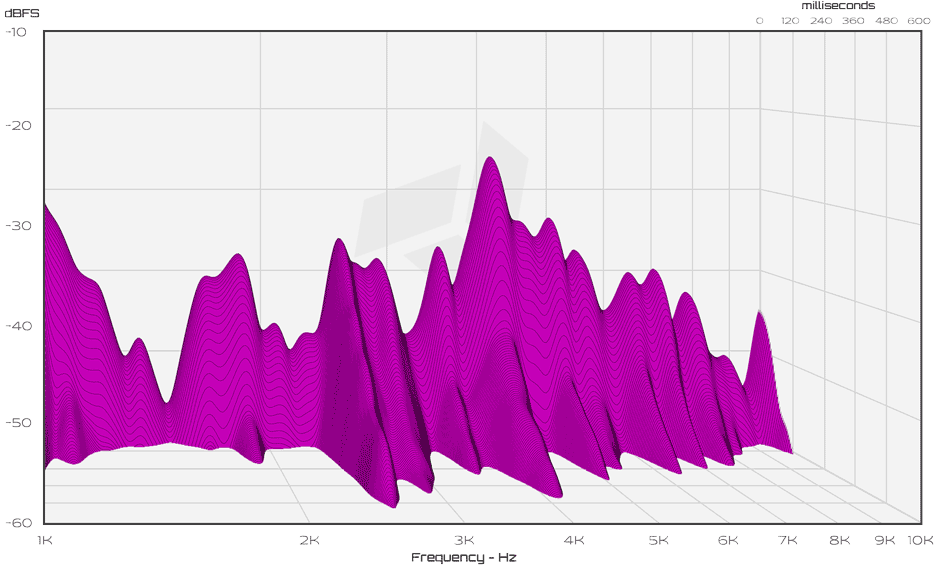

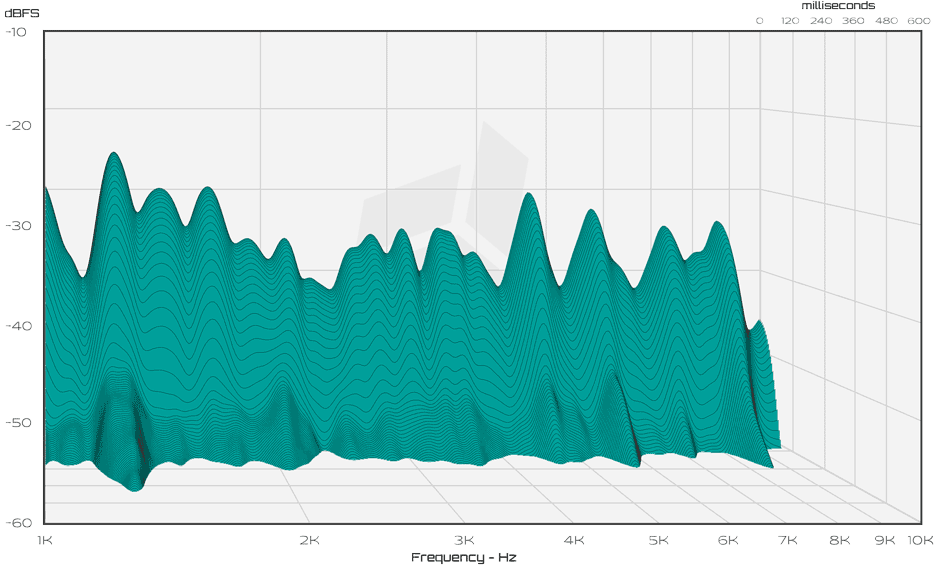

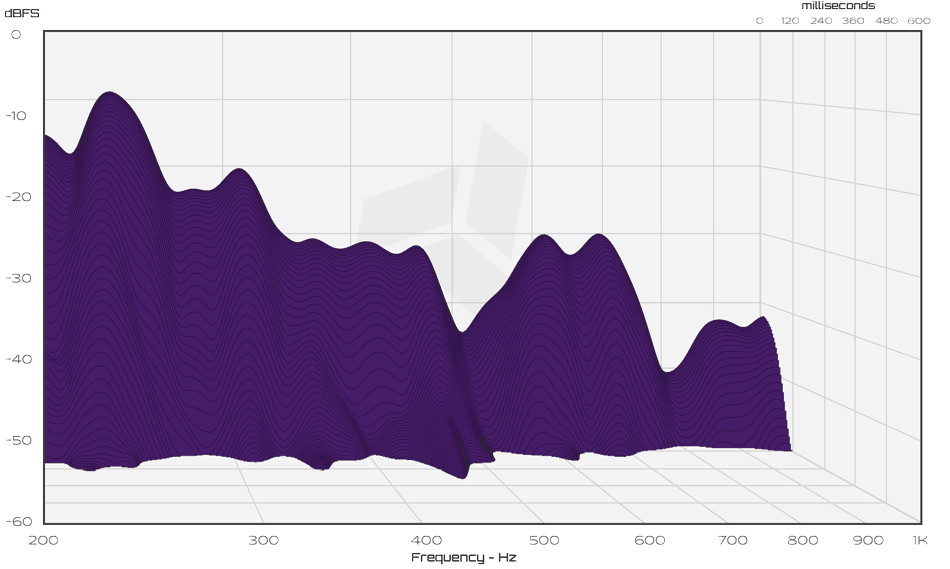

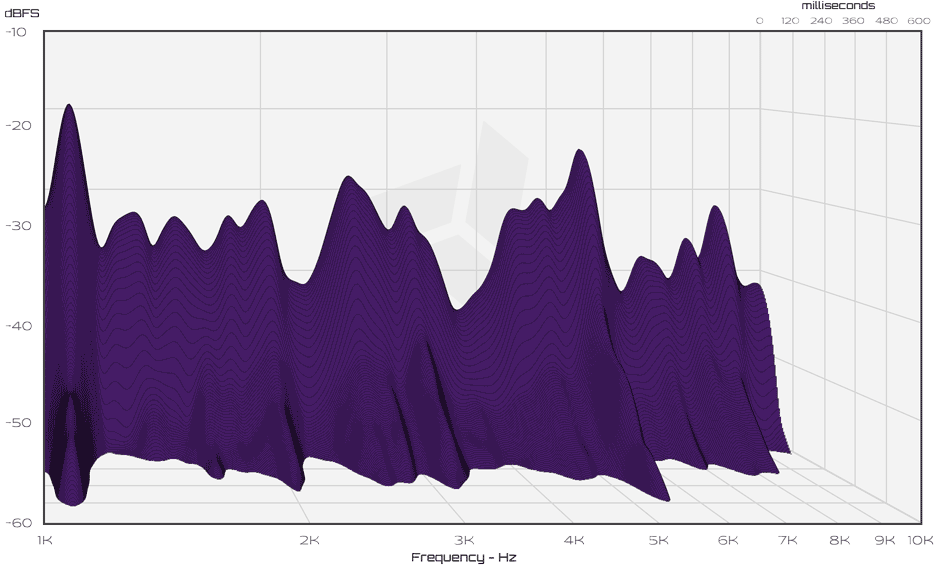

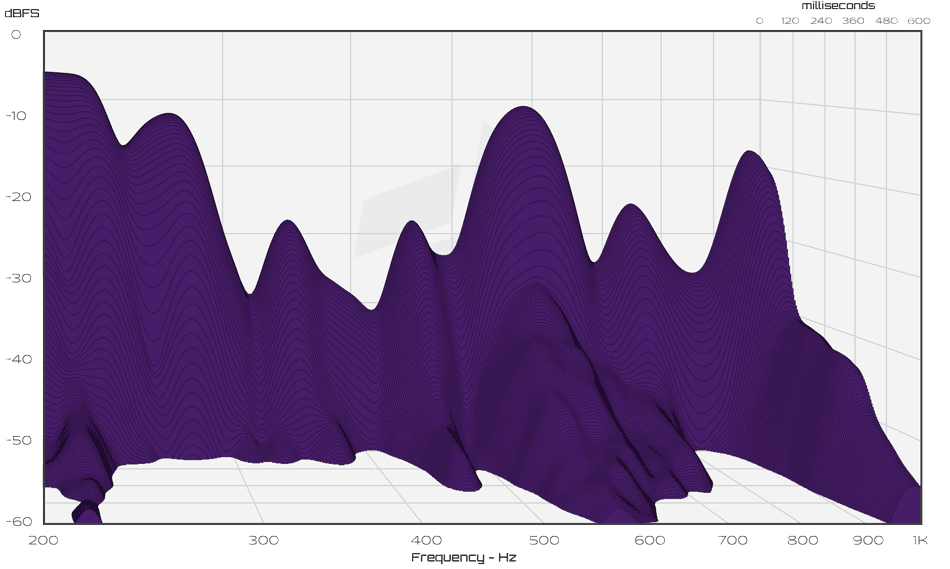

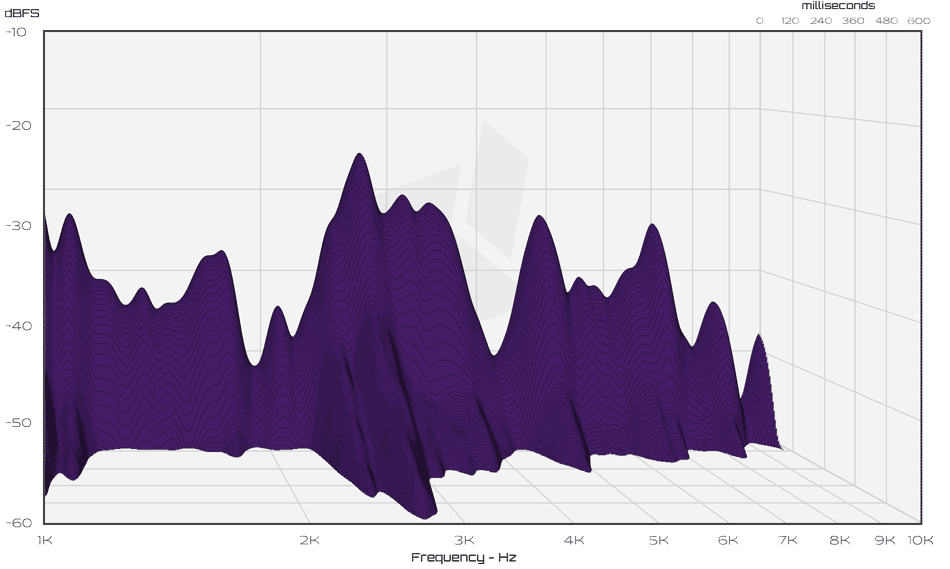

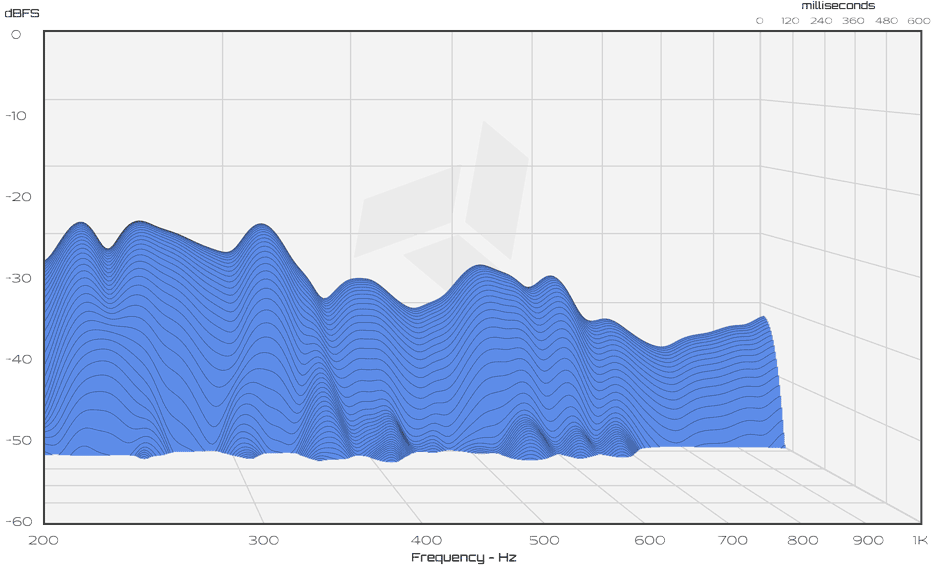

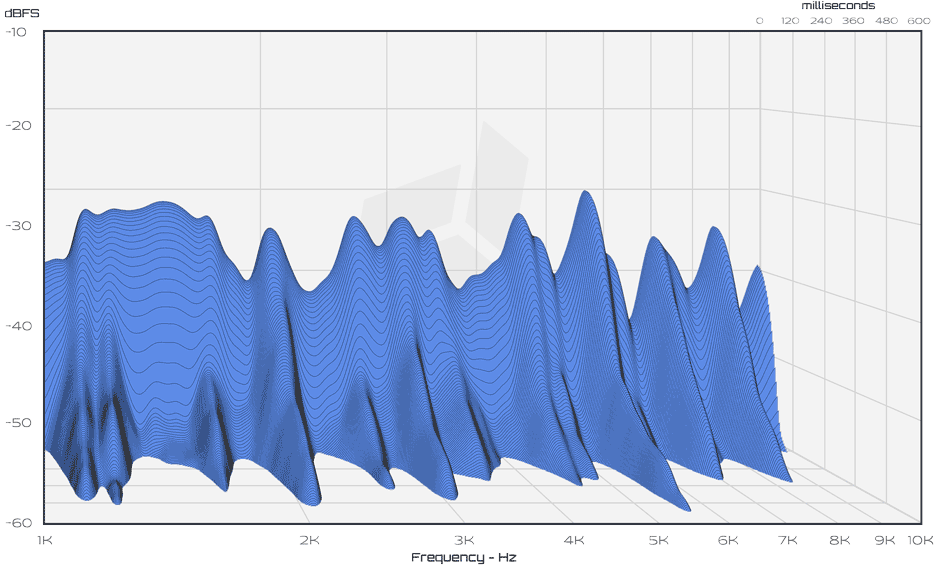

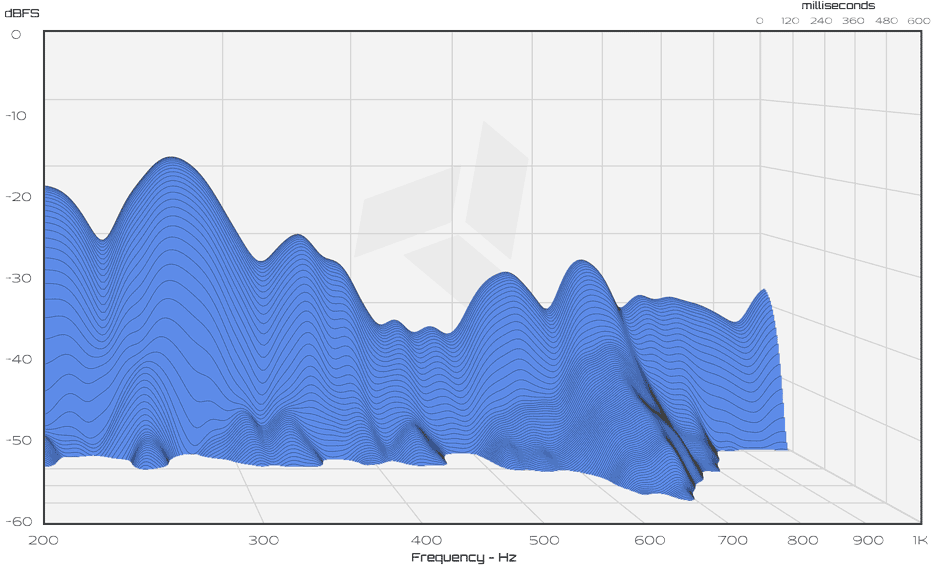

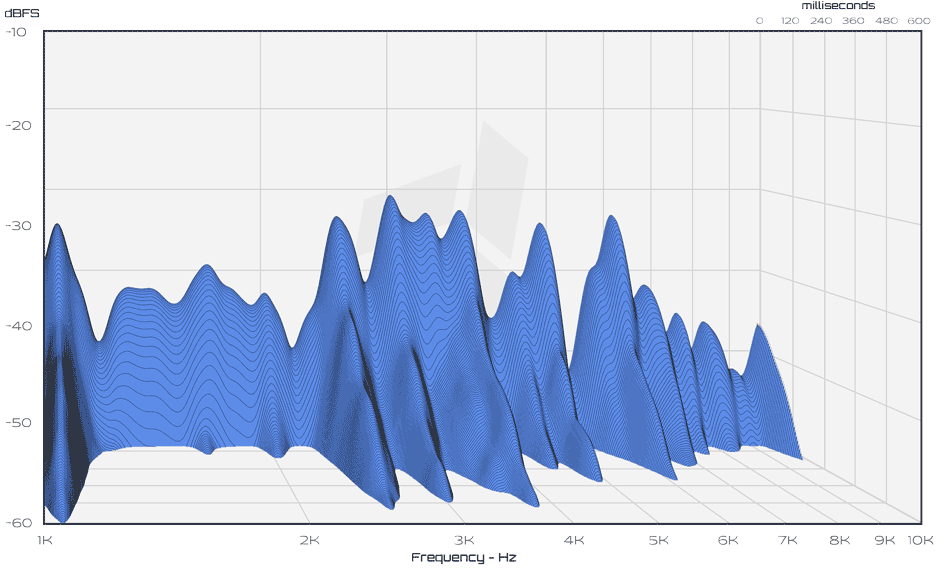

2-Way Loudspeaker

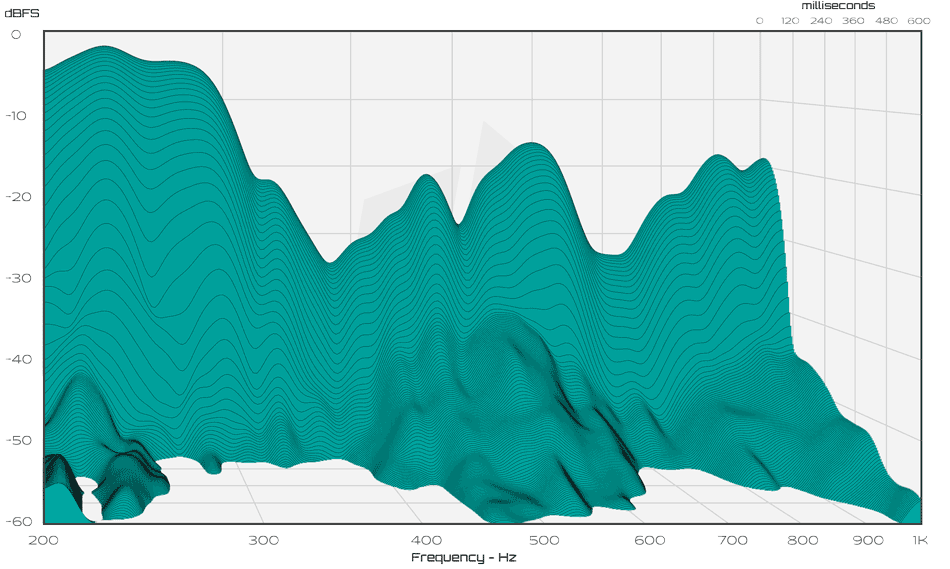

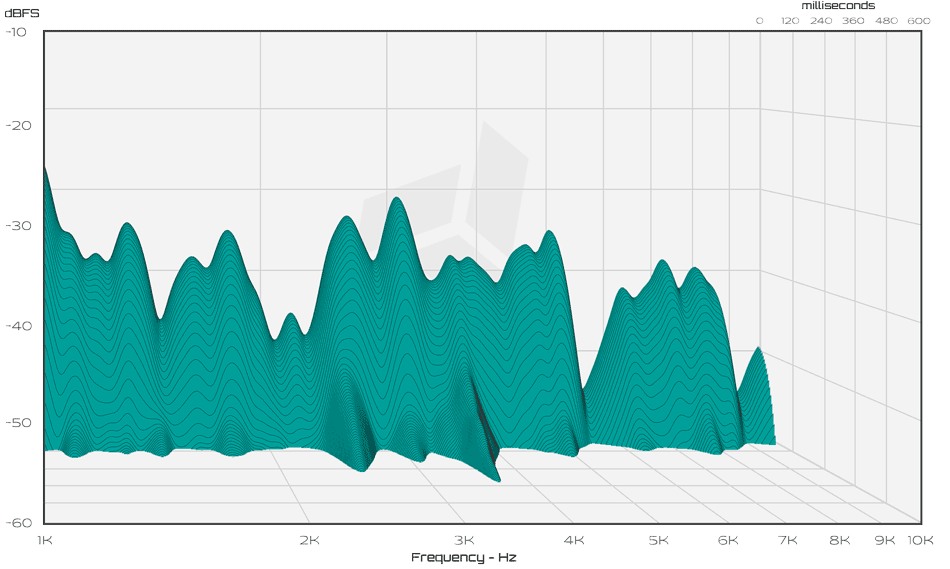

A 2-way loudspeaker was used as a vibration source to obtain sweep measurements in the midrange and treble frequency regions. The experiment was conducted using the same process as the subwoofer experiment except that the sweeps were done from 200 Hz to 1 kHz for the midrange and 1 kHz to 10 kHz for the treble. Another difference was that the accelerometer sensor amplifiers were set to provide a +20 dB gain relative to the subwoofer measurements. The additional gain was applied due to the inherently lower vibration amplitude of higher frequencies. The higher gain also raised the noise floor, which required limiting the visible portion of the mid and high frequency waterfall graphs to avoid noise floor artifacts. The maximum SPL of the loudspeaker was also 93 dBA during the sweeps with the driving voltage held constant throughout all measurements. This maximum horizontal cabinet acceleration experienced during the sweeps was 1.9 m/s2.

The advantages of the subwoofer and loudspeaker experiments were that they offered a high resolution view of the vibration decay behavior of each audio footer. The disadvantages were that the vibration of the cabinets were not as consistent with frequency as it was in the vibration table experiment. The vibration behavior of the cabinets were consistent between measurements however, allowing for useful relative comparisons between audio footers. Each measurement was taken twice consecutively and then averaged to smooth irregularities in the vibration behavior of the cabinets.

Click on the Measurements text under each device to toggle visibility of its graphs.

Horizontal and Vertical measurements are shown on separate tabs.

Disclaimers

These experiments simulated the vibration amplitudes experienced directly at the cabinet of a loudspeaker or subwoofer playing at moderate to high volume. Some audio footers may measure differently when isolating lower amplitude vibrations. Additionally, the mass being supported influences the performance of some audio footers, so changing the mass can change the measurements. Finally, these measurements were all taken with an approximately steady state sinusoidal vibration stimulus which is different from the dynamic state of music.

Conclusion

The vibration isolation performance of the audio footers tested varied significantly. In most cases, unwanted stray vibrations increased through the footers in the bass and lower midrange frequencies. In other cases, damping was insufficient causing resonances to continue long after the initial stimulus, as indicated by the long decay times in some of the waterfall graphs.

The Carbide Base footers were unique in their superior ability to isolate and damp the bass and lower midrange thus maximizing clarity across these frequencies.